A prominent US Integrated Delivery Network (IDN) leveraged Xerafy’s expertise in hospital SPD reprocessing and autoclavable healthcare RFID to revolutionize their surgical tray workflows.

Working with a solution provider specializing in surgical logistics management, they achieved real-time visibility, enhanced compliance, and streamlined operations for surgical instrumentation and interdepartmental workflows.

Both the health system and the solution provider chose to remain anonymous to maintain confidentiality while highlighting the transformative outcomes of this initiative.

Challenges and Problems in SPD

The health system’s Sterile Processing Department (SPD) is tasked with ensuring surgical instrumentation is cleaned, disinfected, sterilized, and ready for use at the 18 hospitals in the network.

A single hospital processes between 500 to 1000 instrument trays daily, including hospital-owned and loaner trays managed by manufacturers for specific surgical cases. The SPD’s responsibilities are pivotal for patient care outcomes and operational efficiency.

Key challenges faced include:

Real-time Tray Location Tracking: The ability to locate instrument trays at all times is critical to patient care and operational workflows.

Sterilization Compliance: Ensuring all trays meet sterilization criteria at designated areas within the SPD.

Data Collection Gaps: Manual data collection methods often yield incomplete and unreliable metrics, hindering operational insights and efficiency.

The data collected through efficient tracking and sterilization processes is instrumental in improving operations, productivity, and inventory management in a high-demand environment.

RFID Tracking Solutions to Hardwire Patient Safety and Compliance

To address these challenges, the IDN launched an initiative to enhance patient safety, streamline operations, and ensure regulatory compliance in the SPD and Operating Room (OR) environments.

Key Features of the software solution include:

Cloud-Based Platform: The supplier’s software provides a centralized, cloud-based platform for real-time surgical asset management, ensuring seamless interdepartmental workflows.

Automated Tracking Capabilities: The system integrates RFID and barcode technologies to provide comprehensive visibility into tray usage, location, maintenance, and sterilization history.

Item-Level Tracking: Each individual item inside the tray is associated with the tray/set IDs as a parent-child association, and with the scanning of the tray, each item inside is marked checked as well.

Critical Step Alerts: The combined functionality of Xerafy RFID tags and the supplier’s software platform generates alarms if any critical step is missed, notifying SPD staff immediately.

Selecting Autoclavable RFID Tags for Sterile Processing

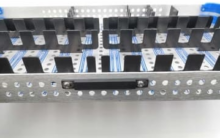

The implementation of RFID technology in sterile environments requires robust tags that can withstand extreme sterilization conditions, including high temperatures and pressures. The health system and the solution provider selected the MICRO Autoclavable RFID tag supplied by Xerafy.

Xerafy offers a range of autoclavable RFID tags designed for healthcare applications, ensuring reliable performance and durability in demanding conditions.

Examples of Xerafy’s autoclavable tags:

ROSWELL Autoclavable – An ultra-rugged tagging solution for all types of surgical trays and containers, this tag combines biocompatible materials with durability at the highest temperatures, optimizing workflow efficiency in the SPD.

MICRO Autoclavable – Compact and rugged, this tag is ideal for tracking all surgical trays, offers extended read range and high resistance to repeated reprocessing cycles.

MICRO Medical – Designed specifically for medical device manufacturers, this compact tag ensures seamless integration and traceability while maintaining compliance with sterilization standards.

These tags, integrated with RFID tracking systems, enable real-time monitoring and data collection, ensuring every instrument and tray meets sterilization requirements and is ready for surgical use. By employing Xerafy’s autoclavable tags, hospitals can improve operational efficiency, reduce errors, and enhance patient safety.

Overcoming Tagging Challenges

The project involved RFID tagging every hospital tray within a timeline that aligned with the OR staff’s ongoing needs.

Maintaining surgical case schedules without disruption, as cases occur 24/7.

Establishing an efficient protocol for pulling and tagging non-surgical trays while ensuring readiness.

Encouraging hospital staff to review collected data regularly to improve processes, manage instrumentation costs, and adopt best practices.

Overcoming the learning curve and fostering a willingness to adapt to new workflows were additional considerations.

Transformative Impact of RFID Technology in Surgical Tray Management

The solution provider’s innovative solutions enhance transparency, scalability, and operational efficiency, making them an essential partner in improving patient safety, compliance, and SPD workflows.

By addressing critical challenges in sterilization and tracking, this RFID tracking solution enables hospitals to prioritize patient safety, enhance operational efficiency, and meet stringent regulatory standards.

Traditional manual data collection methods often resulted in incomplete and unreliable metrics, hindering effective operational insights.

The integration of the supplier’s platform and Xerafy’s Medical RFID technology transformed this process by:

Enhanced Data Collection: Reliable data on tray quantities and utilization.

Maintenance Triggers: Automated utilization metrics prompt timely maintenance of trays and instrumentation.

Efficiency Measurement: Accurate data collection enables better forecasting, staffing models, and operational planning.

Xerafy is a pioneer in Healthcare RFID, bringing to market several innovations that enable advanced identification and automation capabilities in healthcare.

In addition to a complete range of field-proven RFID tags available off-the-shelf, Xerafy offers Custom RFID Tags services, covering everything from a personalization service bureau to custom-design engineering capabilities.