ROSWELL series

Ultra-Rugged RFID Tags for Asset Tracking in the Most Harsh and Demanding Environments

The ROSWELL series from Xerafy epitomizes durability with ultra-rugged RFID tags engineered for the most challenging environments. These tags are ideal for heavy-duty applications in industries such as oil and gas, construction, mining, rail, and healthcare, where tags must endure extreme conditions.

ROSWELL series tags are built to survive high temperatures, intense pressures, and severe mechanical stresses. These tags are also fully waterproof and capable of withstanding prolonged exposure to harsh chemicals and corrosive environments. Designed with a focus on reliability, the ROSWELL tags ensure consistent performance and long-term durability, even when embedded into metal surfaces or used in autoclavable settings.

Developed to meet the rigorous demands of industrial applications, ROSWELL tags are trusted by global leaders in sectors that require the highest standards of tag resilience and data integrity. These tags have proven their worth in the field, demonstrating superior durability and reliability in mission-critical tracking operations be they above or below ground.

“Considering the environment and working conditions the tag would have to endure, the mounting options available to us, and the surfaces we would need to work with, the Xerafy ROSWELL ticked all the boxes.”

With the ROSWELL series, the award-winning Xerafy engineering team offers a patented design that includes options for flush mounting or secure attachment using welding, rivets, or screws. Each tag is crafted from high-grade materials like stainless steel, aluminum, and high-performance engineered polymers, ensuring peak performance under extreme industrial conditions.

The tags are available in an autoclavable version for medical and food processing applications and ATEX-certified versions for safe deployment in explosive atmospheres.

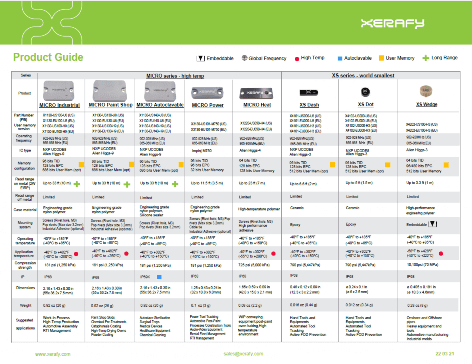

For a broader spectrum of RFID tagging solutions, Xerafy offers several rugged series tailored to different needs: the MICRO series for high-temperature environments, the PICO series for small sizes, and the XS series for the smallest size requirements.

Ultra Rugged RFID Tags That Stand Out

The ROSWELL series of passive on-metal RFID tags offer tagging solutions for hazardous environments

while performing reliably under the most stringent circumstances

Ultra Rugged

Resistance to high temperatures, pressure, compression, chemicals, oils, fluids

Antenna-free Design

Intrinsically resistant to compression, pressure, shocks and vibrations

Omni Direction

Full 180-degree read orientation in the field

Embed, Rivets And More

Rugged metal mounting options: Rivets, Screws, Welding, Flush mounting

ATEX/IECEx

For explosive atmospheres and hazardous environments

Unique ID

Memory for item-level identification and secure data encoding

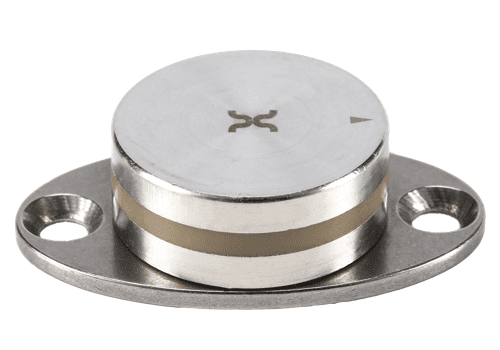

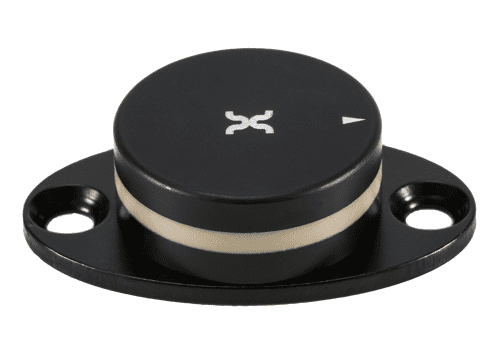

ROSWELL Autoclavable

World's Most Rugged Tag

The ROSWELL Autoclavable sets the standard for ultra-rugged RFID durability, with a stainless steel-encased tag engineered to withstand high-temperature cycling, extreme vibrations, and compression.

Designed for autoclave environments and other high-heat industrial applications, it ensures long-term reliability even under repeated exposure to intense heat and pressure. Optimized for FDA UDI compliance for surgical trays and medical devices, the ROSWELL Autoclavable supports seamless asset tracking and regulatory adherence in mission-critical environments.

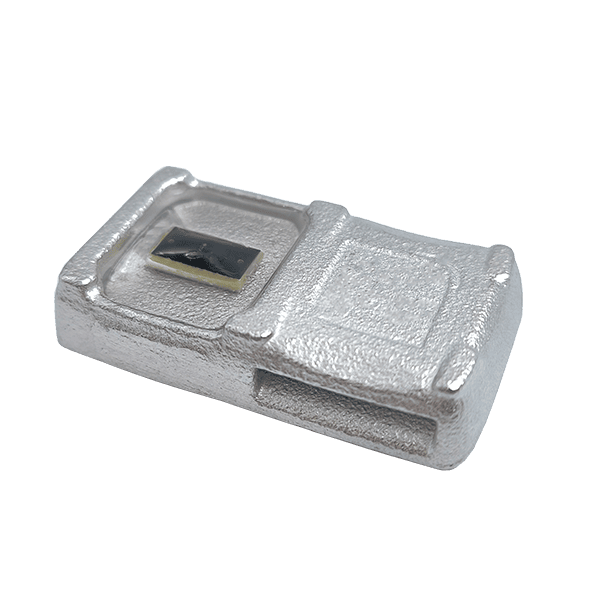

ROSWELL

Best For Hazardous Environments

The ROSWELL transforms RFID tracking in hazardous environments with its innovative antenna-free design, delivering unmatched durability and signal integrity where conventional tags fail.

Constructed from shock-resistant aluminum, it withstands extreme heat, harsh chemicals, abrasion, and impact, making it ideal for demanding industrial conditions. Certified for ATEX zones, the ROSWELL ensures reliable RFID performance in environments where traditional asset tags degrade.

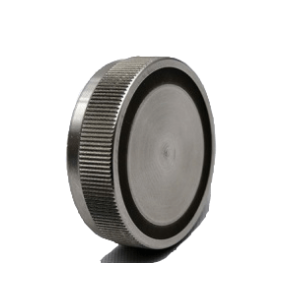

XPLORER Downhole

First Ultra-Rugged for Downhole

The XPLORER Downhole is engineered for high-temperature, high-pressure environments, ensuring long-term RFID performance in extreme downhole conditions.

Its robust, round form factor allows for flush embedding into tubulars and drill bits, while its vibration-resistant and chemical-resistant construction ensures durability in deep drilling, completions, and wellbore monitoring. Tuned for downhole operations with drilling fluids and water, it delivers reliable tracking and data integrity in high-temperature, high-pressure wells where traditional RFID tags degrade.

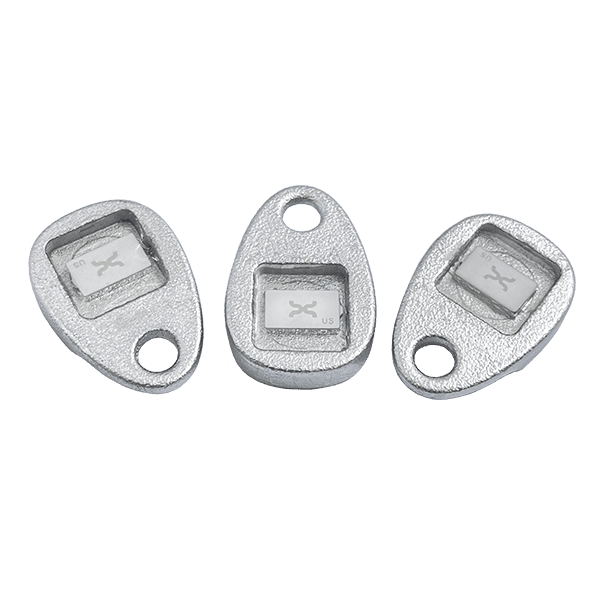

XPLORER

Ultra-Rugged Embeddable RFID Tag

The XPLORER is an ultra-rugged embeddable RFID tag designed for applications where extreme durability and metal integration are critical.

Encased in durable stainless steel, it withstands high temperatures, chemical exposure, and heavy impacts, ensuring long-term performance in the harshest conditions. Optimized for flush mounting in metal, the XPLORER provides long-lasting RFID performance for industrial assets requiring embeddable tracking in extreme environments.

PIPETRACKER Band

Ultra-Rugged Metal Band Tag for Tubulars

The PIPETRACKER Band is an ultra-rugged UHF RFID tag designed for long-range tracking of surface pipes, frac iron, and industrial tubing in Oil & Gas, Mining, and Construction.

Encased in a protective stainless steel housing, the PIPETRACKER Band withstands abrasion, impact, and extreme weather conditions for reliable identification in harsh environments. Its secure metal band attachment ensures fast installation, firm positioning, and easy relocation, making it an ideal choice for long-term tubular asset management.

TACKTAG

Weldable Ultra-Rugged Metal Tag for Equipment

The TACKTAG is an ultra-rugged UHF RFID tag designed for permanent, weld-on attachment, ensuring lifetime tracking of tools, machinery, and industrial equipment in Oil & Gas, Mining, Construction, and Heavy Manufacturing.

The TACKTAG is engineered to withstand high temperatures, chemicals, and physical stress, making this compact form factor an ideal solution for tool tracking in hazardous environments.

DURADROP

Ultra-Rugged Hang Tag for Rigging & Lifting

The DURADROP is a rugged, reusable stainless steel RFID hang tag built for long-term tracking and inspection automation in lifting, rigging, and industrial safety applications across Oil & Gas, Mining, Construction, and Manufacturing.

Its high-impact stainless steel design resists abrasion, chemicals, and extreme conditions, delivering reliable performance in extreme environments. The pre-drilled mounting hole allows secure attachment and repositioning on wire rope slings, chain slings, fall protection lanyards, and lifting equipment, making it an efficient solution for equipment inspection, certification, and lifecycle management.

DURAZIP

Durable Cable Tie Tag for Rigging & Lifting

The DURAZIP is a durable, quick-install UHF RFID tag designed for industrial asset tracking in lifting, rigging, safety, and inspection automation across Oil & Gas, Mining, Construction, and Power Utilities.

Featuring a stainless steel cable tie attachment, it enables fast, flexible deployment on chains, valves, pipes, and steel wire ropes without requiring drilling or welding. Its impact-resistant RFID module ensures durability in abrasive, high-impact environments, while its 360º read orientation and up to 1.5 meters of read range provide efficient real-time asset traceability.

DUALBAND NFC

Dual UHF+NFC Durable Tag For Tubulars

The DUALBAND NFC is a durable dual-frequency UHF RFID+NFC tag engineered for seamless identification and tracking of cylindrical industrial assets in Oil & Gas, Mining, Renewables, and Energy.

Designed for demanding field conditions, the DUALBAND NFC features slotted holes for secure banding onto industrial hoses, frac iron, lifting shackles, and high-pressure canisters. The dual-frequency capability supports long-range UHF RFID tracking while allowing mobile device interaction via NFC, enhancing field operations.

Can ROSWELL RFID Tags be customized?

All the RFID tags in the ROSWELL series can be fully

personalized to support the deployment of your RFID system

Printing

Support for printing of serial numbers, IDs, Logo, 1D and 2D Barcodes

Marking

Support for permanent laser marking

Encoding

Support unique IDs and EPC serialization for item-level tracking

Engineering

Support custom engineering: ATEX, backplate, frequency...

Case Studies

On metal RFID tags with extreme rugged features like the Xerafy ROSWELL series enable passive UHF asset tracking capabilities in systems designed for the most challenging operations in the field:

FAQs RFID Tagging with ROSWELL series

What are the ROSWELL series RFID tags used for?

The ROSWELL series of RFID tags are specifically designed for use in harsh environments. These tags are able to survive repeated high temperatures and pressure cycles, making them ideal for tracking assets in industries such as Oil and Gas, Mining, Hi-Temp Manufacturing, Chemicals, and Healthcare.

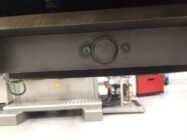

Oil and Gas drill pipes featuring Xerafy XPLORER Downhole tags

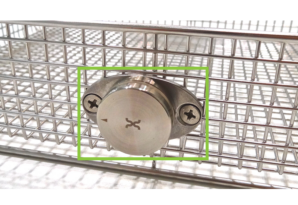

Oilfield equipment featuring a Xerafy ROSWELL Autoclavable tag

The extra-rugged stainless steel or aluminum cases of these tags makes them the ideal tagging solution to track assets in these extreme conditions.

Can ROSWELL series RFID tags survive an autoclave?

Yes, the ROSWELL Autoclavable RFID tag can survive autoclave in manufacturing as well as in medical environments.

Surgical tray featuring a Xerafy ROSWELL Autoclavable tag

The tag has been qualified by medical device manufacturers as well as by hospitals for sterilization cycles such as CSSD/SPD re-processing.

What are the maximum temperature and pressure for ROSWELL series RFID tags?

The XPLORER Downhole tags are qualified to survive repeated cycles of 250 °C high temperatures and 13,000 psi high pressure.

Can the ROSWELL series RFID tags withstand acid and alkali?

Yes, the tags’ respective stainless steel and aluminum casing offer protection against varying types and concentrations of acid or alkali typical of industrial environments, including:

+ Drilling fluids

+ Hydraulic fluids including hydrogen sulphide

+ H2SO4 (10% sulfuric acid)

+ HNO3 (10% nitric acid)

+ H3PO4 (20% phosphoric acid)

+ H2O2 (25% hydrogen peroxide)

+ NaOH (10% sodium hydroxide)

Some acids or alkalis may corrode or damage the tag over time, while others may have little to no effect. The Xerafy Engineering team can advise on the tagging solutions best suited to the environmental conditions in which the tags will be used and assist with testing.

Are the ROSWELL series RFID tags ATEX/IECEx compliant?

Yes, the ROSWELL series RFID tags are available in ATEX/IECEx compliant versions.

ATEX/IECEx-certified RFID tags are intrinsically safe to operate in explosive atmospheres in the presence of gas, vapor, mist, powder, or dust.

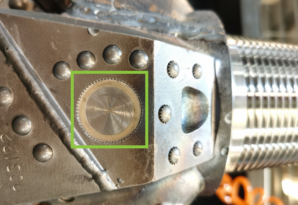

How to securely embed an XPLORER RFID tag in a drill pipe?

The XPLORER RFID tags can be embedded in metal assets, such as drill pipes, drill bits, or downhole equipment.

Mining drill bit featuring a Xerafy XPLORER tag

Flush mounting best practices and support are available from the Xerafy Engineering team for a variety of specific assets.