ROSWELL series

Ultra-Rugged RFID Tags for Asset Tracking in the Most Harsh and Demanding Environments

The ROSWELL series from Xerafy sets the standard for rugged RFID, offering the most comprehensive portfolio of ultra-durable tags in the market.

Developed for the toughest industrial environments, ROSWELL delivers unmatched resilience where other RFID asset tags fail: from oilfield drilling and heavy construction to rail, inspections, safety equipment, and healthcare sterilization.

ROSWELL series tags are engineered to withstand heat, pressure cycles, corrosive fluids, and repeated mechanical stresses. Fully waterproof and chemically resistant, they maintain reliable performance even when embedded in metal or exposed to cleaning and sterilization processes. With 10 specialized SKUs, the ROSWELL series offers the most comprehensive range of ultra-rugged RFID on the market, ensuring consistent performance from downhole drilling to inspections, safety equipment, and working at height.

Co-developed with industry leaders in mission-critical operations, ROSWELL series adapts to the realities of field deployment with domain-specific mounting options including banding, zip ties, screw-in, weldable, and flush installation. This flexibility ensures the right fit for assets ranging from drill pipes and tubulars to valves, carabiners, and protective equipment.

“Considering the environment and working conditions the tag would have to endure, the mounting options available to us, and the surfaces we would need to work with, the Xerafy ROSWELL ticked all the boxes.”

Each ROSWELL tag features a patented design built with stainless steel, aluminum, and engineered polymers for maximum durability. Specialized versions extend its reach: autoclavable tags for healthcare and food processing, and ATEX-certified models for explosive atmospheres.

If the MICRO series stands for heat resistant RFID tag and the XS, PICO series are optimized for size, the ROSWELL series represents the apex of Xerafy RFID tags for asset tracking: delivering the broadest range, the deepest field experience, and the highest reliability where performance cannot be compromised.

Ultra Rugged RFID Tags That Outperform

The ROSWELL series of passive on-metal RFID tags offer tagging solutions for hazardous environments

while performing reliably under the most stringent circumstances

Ultra Rugged

Resistance to high temperatures, pressure, compression, chemicals, oils, fluids

Antenna-free Design

Intrinsically resistant to compression, pressure, shocks and vibrations

Omni Direction

Full 180-degree read orientation in the field

Embed, Rivets And More

Rugged metal mounting options: Rivets, Screws, Welding, Flush mounting

ATEX/IECEx

For explosive atmospheres and hazardous environments

Unique ID

Memory for item-level identification and secure data encoding

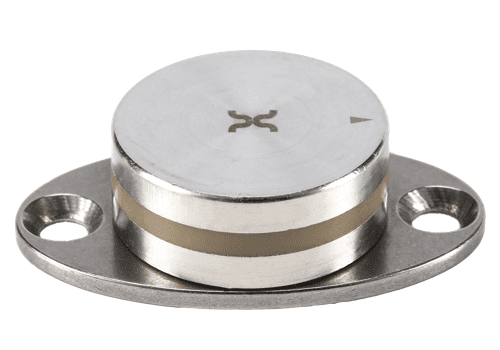

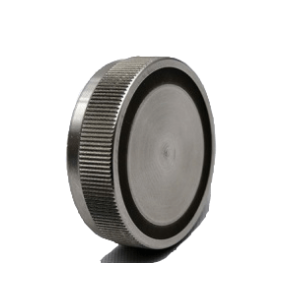

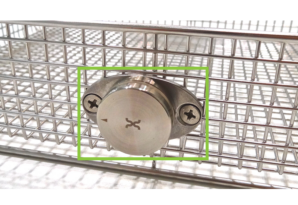

ROSWELL Autoclavable

World's Most Rugged Tag

The ROSWELL Autoclavable sets the standard for ultra-rugged RFID durability, with a stainless steel-encased tag engineered to withstand high-temperature cycling, extreme vibrations, and compression.

Designed for autoclave environments and other high-heat industrial applications, it ensures long-term reliability even under repeated exposure to intense heat and pressure. Optimized for FDA UDI compliance for surgical trays and medical devices, the ROSWELL Autoclavable supports seamless asset tracking and regulatory adherence in mission-critical environments.

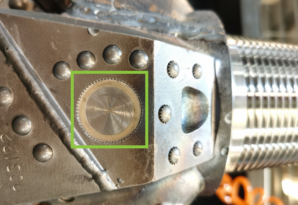

XPLORER Screw

Embeddable Tag for OCTG and Industrials

The XPLORER Screw is an in-metal embeddable RFID tag engineered for OCTG and industrial tubular assets requiring a secure and field-serviceable installation.

Its M24 threaded interface positions the tag fully within the metal envelope, providing a protected mount that supports inspection and replacement in the field. Designed for OCTG tubulars, drill pipe accessories, workover assemblies, and industrial piping, the XPLORER Screw delivers up to 5 meters of read range when embedded in steel and withstands the mechanical loads, shock, vibration, and fluid exposure of drilling, well intervention, subsea, LNG, and other critical operations.

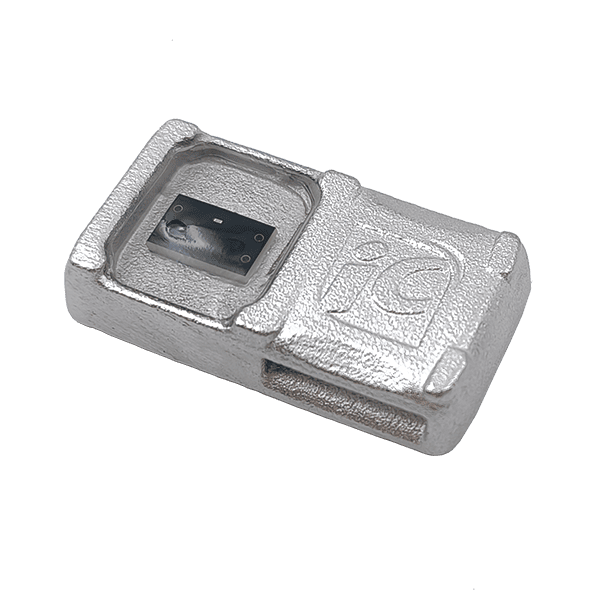

XPLORER Surface

The Toughest Embeddable In-Metal Tag

The XPLORER Surface is engineered for surface-level and shallow-embedded applications where impact, vibration, and corrosion threaten asset identification.

Its stainless-steel body withstands high temperatures, intense mechanical forces, and chemical exposure without loss of performance. Optimized for flush mounting in pipes, rigging, lifting equipment, mining machinery, and high-temperature process vessels, it ensures long-term asset tracking and inspection traceability in the harshest topside conditions.

PIPETRACKER2

Ultra-Rugged Metal Tag for Tubulars

The PIPETRACKER2 is an ultra-rugged UHF RFID tag designed for long-range tracking of surface pipes, frac iron, and industrial tubing in Oil & Gas, Mining, and Construction.

Encased in a protective stainless steel housing, the PIPETRACKER2 withstands abrasion, impact, and extreme weather conditions for reliable identification in harsh environments. Its secure metal band attachment ensures fast installation, firm positioning, and easy relocation, making it an ideal choice for long-term tubular asset management.

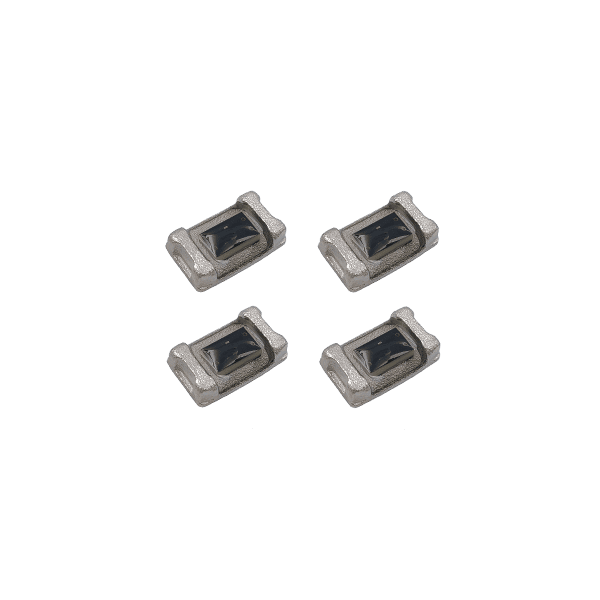

TACKTAG2

Weldable Ultra-Rugged Metal Tag for Equipment

The TACKTAG2 is an ultra-rugged UHF RFID tag designed for permanent, weld-on attachment, ensuring lifetime tracking of tools, machinery, and industrial equipment in Oil & Gas, Mining, Construction, and Heavy Manufacturing.

The TACKTAG2 is engineered to withstand high temperatures, chemicals, and physical stress, making this compact form factor an ideal solution for tool tracking in hazardous environments.

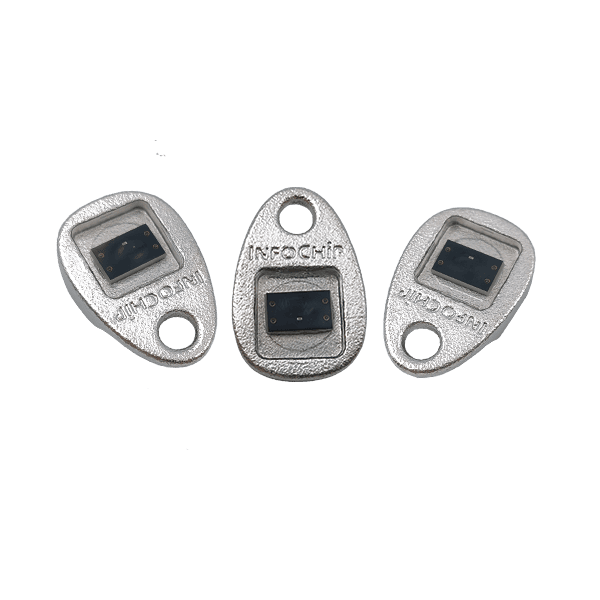

DURADROP

Ultra-Rugged Hang Tag for Rigging & Lifting

The DURADROP is a rugged, reusable stainless steel RFID hang tag built for long-term tracking and inspection automation in lifting, rigging, and industrial safety applications across Oil & Gas, Mining, Construction, and Manufacturing.

Its high-impact stainless steel design resists abrasion, chemicals, and extreme conditions, delivering reliable performance in extreme environments. The pre-drilled mounting hole allows secure attachment and repositioning on wire rope slings, chain slings, fall protection lanyards, and lifting equipment, making it an efficient solution for equipment inspection, certification, and lifecycle management.

DURAZIP

Durable Cable Tie Tag for Rigging & Lifting

The DURAZIP is a durable, quick-install UHF RFID tag designed for industrial asset tracking in lifting, rigging, safety, and inspection automation across Oil & Gas, Mining, Construction, and Power Utilities.

Featuring a stainless steel cable tie attachment, it enables fast, flexible deployment on chains, valves, pipes, and steel wire ropes without requiring drilling or welding. Its impact-resistant RFID module ensures durability in abrasive, high-impact environments, while its 360º read orientation and up to 1.5 meters of read range provide efficient real-time asset traceability.

DATABAND2 NFC

Dual UHF+NFC Durable Tag For Tubulars

The DATABAND2 is a durable dual-frequency UHF RFID+NFC tag engineered for seamless identification and tracking of cylindrical industrial assets in Oil & Gas, Mining, Renewables, and Energy.

Designed for demanding field conditions, the DATABAND2 features slotted holes for secure banding onto industrial hoses, frac iron, lifting shackles, and high-pressure canisters. The dual-frequency capability supports long-range UHF RFID tracking while allowing mobile device interaction via NFC, enhancing field operations.

Can ROSWELL RFID Tags be customized?

All the RFID tags in the ROSWELL series can be fully

personalized to support the deployment of your RFID system

Printing

Support for printing of serial numbers, IDs, Logo, 1D and 2D Barcodes

Marking

Support for permanent laser marking

Encoding

Support unique IDs and EPC serialization for item-level tracking

Engineering

Support custom engineering: ATEX, backplate, frequency...

Case Studies

On metal RFID tags with extreme rugged features like the Xerafy ROSWELL series enable passive UHF asset tracking capabilities in systems designed for the most challenging operations in the field:

FAQs RFID Tagging with ROSWELL series

What are the ROSWELL RFID tags used for?

ROSWELL tags are specifically designed for use in harsh environments thanks to their extra-rugged stainless steel or aluminum cases.

Oil and Gas drill pipes featuring Xerafy XPLORER Downhole tags

Oilfield equipment featuring a Xerafy ROSWELL Autoclavable tag

Each RFID metal tag is able to survive repeated high temperatures and pressure cycles, vibrations and impact, making them the ideal RFID tags for manufacturing and other demanding industries:

+ Oil and Gas

+ Mining

+ Chemicals

+ Construction

+ Healthcare

Are ROSWELL tags compatible with standard RFID readers and software?

Yes. All ROSWELL tags are fully compliant with the EPC Gen2 / ISO 18000-63 (RAIN RFID) standard, making them compatible with industry-standard RFID readers and software platforms.

This ensures seamless integration into existing systems for asset tracking, inspection, and compliance workflows without requiring proprietary infrastructure.

What are the maximum temperature and pressure for ROSWELL RFID tags?

The XPLORER tags are qualified to survive repeated cycles at temperatures as high as 250°C high or pressure of up to 22,000 psi.

Can the ROSWELL series RFID tags withstand acid and alkali?

Yes. ROSWELL tags are designed to operate in environments with exposure to common industrial chemicals. They have been tested for resistance to drilling fluids, hydrogen sulfide, acids, and caustics typically encountered in oilfield, mining, and industrial processes.

Resistance levels depend on the specific substance and duration of exposure, so for long-term deployments Xerafy recommends consultation with our engineering team to validate the application and ensure optimal tag selection.

Can ROSWELL series RFID tags survive an autoclave?

Yes, the ROSWELL Autoclavable RFID tag can survive autoclave in manufacturing as well as in medical environments.

Surgical tray featuring a Xerafy ROSWELL Autoclavable tag

The tag has been qualified by medical device manufacturers as well as by hospitals for sterilization cycles such as CSSD/SPD re-processing.

Are the ROSWELL tags ATEX/IECEx compliant?

Yes, the ROSWELL series RFID tags are available in ATEX/IECEx compliant versions.

ATEX/IECEx-certified RFID tags are intrinsically safe to operate in explosive atmospheres in the presence of gas, vapor, mist, powder, or dust.

What are the mounting options available for ROSWELL tags?

ROSWELL tags support a wide range of secure mounting methods to suit different asset types and environments.

Secure permanent and replaceable mounting options include:

+ Brackets for rivets

+ Flush embedding in drill pipes and tools

+ Threaded screw-in for precise positioning

+ Weldable options for permanent, high-strength attachment

+ Banding on pipes, tubulars, and cylinders

+ Zip ties for cables, hoses, and smaller equipment

+ Hanging for rigging, lifting gear, and safety equipment that require quick, non-invasive attachment

Each mounting method is engineered to withstand vibration, impact, and harsh environmental conditions, ensuring long-term reliability across industrial applications.

How are ROSWELL tags banded to pipes and tubulars?

ROSWELL tags such as the PIPETRACKER are designed for secure banding to tubulars, pipes, and similar assets. Installation is performed using stainless steel bands or certified strapping systems, which ensure the tag remains firmly attached during handling, transport, and operation.

Xerafy provides application guides and recommended banding materials to support reliable performance in demanding environments.

How are XPLORER RFID tags embedded in drill pipes?

The Xerafy XPLORER are embeddable RFID tags engineered for flush mounting into drill pipes and downhole tools, ensuring they remain protected while delivering reliable identification throughout their lifecycle.

Mining drill bit featuring a Xerafy XPLORER tag

Embedding is performed using industry-standard machining processes, and Xerafy provides detailed guidelines as well as application-specific test packs to support validation.

Our engineering team can assist with mounting design, installation procedures, and performance verification, ensuring the embedded tags meet operational requirements before full-scale deployment.

Is it possible to evaluate ROSWELL tags before deployment?

Yes. Xerafy offers application-specific Test Packs that allow operators to validate ROSWELL tags in real-world conditions.

Test Packs include a selection of tag models and mounting options, along with best practices for installation and performance evaluation. This approach helps de-risk projects by ensuring that the chosen tag meets operational requirements before full-scale deployment.