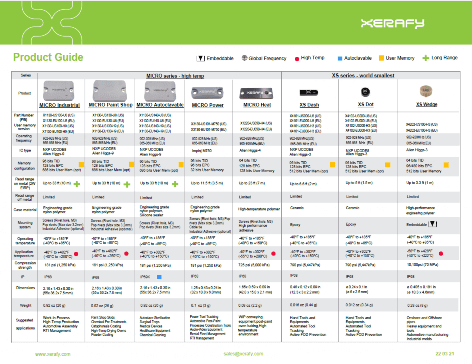

MICRO series

High-Reliability RFID Tags for Rugged On-Metal Asset Tracking in Complex Processes: Resistant to High Temperatures, Shocks, and Chemicals

The MICRO series from Xerafy offers precision-engineered, high-temperature, on-metal RFID tags tailored for critical tracking applications in the automotive, manufacturing, and medical device industries. These benchmark-leading tags are built to ensure consistent reliability even under the most extreme conditions.

Designed for the toughest environments, the MICRO series tags excel in withstanding extreme temperatures, mechanical shocks, corrosive chemicals, and high pressures. Fully waterproof and customizable with advanced encoding options, these tags guarantee reliable performance and impeccable data integrity across complex industrial processes.

Co-developed with Fortune 500 companies, the MICRO series tags adhere to the highest standards of performance and reliability and have been field-tested globally.

“We love Xerafy’s range of special metal tags, which never let us down in any of our projects, especially for demanding production environments.”

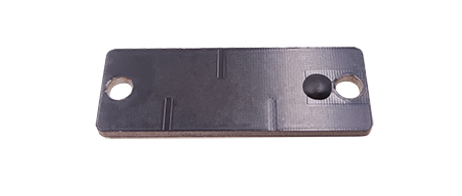

With the MICRO series, our award-winning engineering team pushes the boundaries of RFID technology. Each of the 6 rugged tags combines patented packaging and engineered casing materials to protect the RFID chip from high temperatures, shocks, abrasions, pressure, and corrosives. Metal inserts enhance tag ruggedness, optimizing them for secure attachment with robust mounting systems such as rivets and screws.

For more RFID tagging solutions, the MICRO series is compatible with the PICO series for small tools and equipment, the XS series for the smallest tags, and the ultra-rugged ROSWELL series.

High Temperature RFID Tags That Outperform

Engineered to provide a reusable on-metal tagging solution that

operates reliably in the harshest environments

Rugged

For extreme conditions with Hi-Temp, Chemicals, Pressure and Waterproof

250°C

Up to 500 hours high temp cycling

10 meters

Leading on-metal read range

Stainless Steel Inserts

Reinforced mounting system for M3 rivets, Zip Ties, Industry-grade adhesives

Laser Engraving

Permanent identification in the harshest environments

Unique ID

Memory for item-level identification and data encoding

MICRO Industrial

First Choice For Manufacturing

The Xerafy MICRO Industrial passive RFID tag provides the dependability and ruggedness required in manufacturing and production.

The high temperature UHF RAIN RFID tag is field-proven for harsh environments, where its durability matches the asset's life, thanks to its rugged case and 10 meter on-metal performance.

MICRO Paint Shop

Best For The Paint Shop

The Xerafy MICRO Paint Shop offers an on metal RFID tagging solution for cycling through high temperatures, fluids, and chemicals.

The silicone-free design eliminates the risk of contamination in the shop, and the rugged RFID tag's IP68 rating and high-temperature survival up to 250°C ensure its ruggedness.

MICRO Autoclave

Best For Complex Processes

The Xerafy MICRO Autoclave is a rugged RFID tag purpose-built to withstand the rigors of sterile processing in healthcare.

With its IP69K rating and high-performance engineered polymer case, the on metal RFID tag withstands repeated chemical cleaning and autoclave cycles at high temperatures.

MICRO Medical

Best For Medical Devices

The MICRO Medical is a compact, high-performance RFID tag engineered for surgical instruments and medical devices. It's built with medical-grade material and designed to withstand over 600 autoclave cycles, as well as exposure to harsh sterilization chemicals.

Its IP69K-rated construction offers full protection against water, steam, and dust, making it ideal for high-pressure cleaning and repeated sterilization. Compatible with both metal and plastic surfaces, it ensures reliable tracking without compromising instrument design or functionality.

MICRO Power

Full Performance In Half The Size

The Xerafy MICRO Power delivers full on metal and high temperature RFID performance in a smaller form factor small enough to fit power tools and equipment.

The smaller rugged RFID tag is made of a high-performance engineered polymer for IP68 rating and extra durability against high temperatures and caustic chemicals.

MICRO Heat

The First Choice for High-Temp

The Xerafy MICRO Heat leads all other high-temperature RFID tags with its survivability at up to 215°C.

The rugged RFID tag comes in a compact form factor that delivers a read range of 7 meters on metal. Its selected materials deliver full performance with industry-grade mounting solutions and IP68 rating.

All the RFID tags in the MICRO series can be fully

personalized to support the deployment of an asset tracking RFID system

Printing

Compatible with printing: Serial numbers, IDs, Logo, 1D and 2D Barcodes

Marking

Support for permanent laser marking with case color optimized for optical readability

Encoding

Support unique IDs and EPC serialization for item-level tracking

Engineering

Support custom engineering: Industrial adhesives, ATEX, backplate, sensing features...

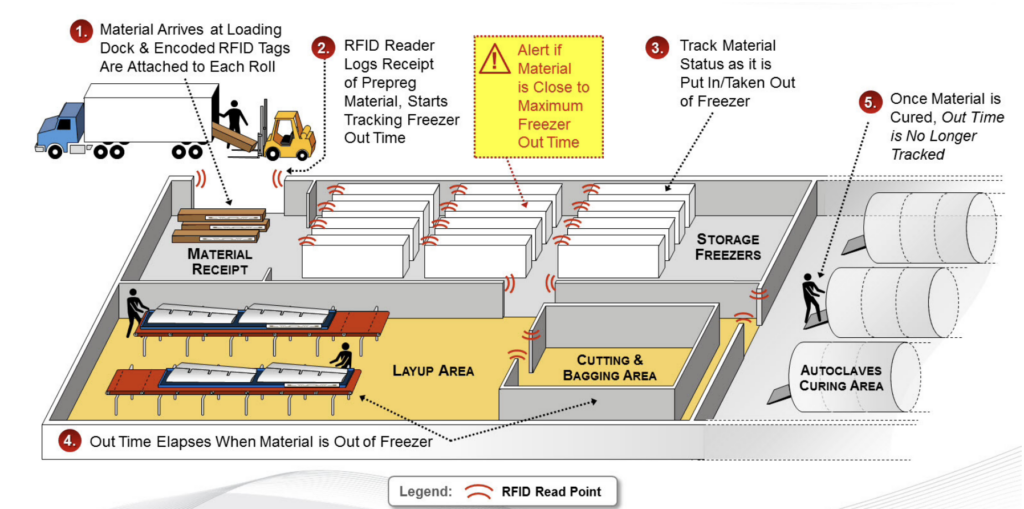

Case Studies

The MICRO series high-temperature RFID tags provide advanced identification and on-metal tracking capabilities to assets in demanding operations:

FAQs RFID Tagging with MICRO Series

What are the MICRO series RFID tags used for?

The Xerafy MICRO series is made of RFID tags for manufacturing (paint shops, work-in-process, production lines…), as well as aerospace, oil and gas, and healthcare.

Their technical features make them the ideal rugged tagging solution to track assets in challenging industries.

Can the MICRO series RFID tags perform on metal surfaces?

Yes, they are specifically designed to perform on metal surfaces.

Ordinary RFID tags cannot be used for metal assets: The metal interferes with RFID signals, causing problems with readability and accuracy. The Xerafy MICRO series, on the other hand, are industrial RFID tags that use antennas designed to work on metal surfaces without interference, as well as techniques such as orientation optimization.

What are the maximum temperatures for MICRO series RFID tags?

The MICRO series RFID tags can survive maximum temperatures of up to 250°C. The tags have also been tested in various high-temperature cycles that are typical of industrial processes such as paint shops.

The Xerafy engineering team can advise on the best tag selection for specific cycles and assist with testing.

Can the MICRO series RFID tags withstand acid and alkali?

Yes, their materials offer protection to varying types and concentrations of acid or alkali typical of industrial environments. Some acid or alkali may corrode or damage the tag over time, while others may have little to no effect.

The Xerafy Engineering team can advise on the tagging solutions best suited to the environmental conditions in which the tags will be used and assist with testing.

Are MICRO series RFID tags waterproof?

Yes, each of the MICRO series tags is waterproof and comes with its own IP rating. The tags are designed to be resistant to water and moisture, making them suitable for use in outdoor or wet environments.

An IP rating, for Ingress Protection, sees the first number referring to protection against solids, and the second number referring to protection against water.

The most common IP ratings for industrial RFID tags are:

- IP54 – Against contamination from limited amounts of dust and other particles, and water sprays from all directions.

- IP68 – Against immersion.

- IP69k – Dustproof and can withstand pressurized washdown at high temperatures.

How reliable are the MICRO series RFID tags?

The MICRO series tags have been thoroughly tested and validated in the field by industry leaders for a range of challenging conditions, including and not limited to:

– Read range on metal and non-metal surfaces

– Read range with fixed and handheld readers

– Radiation pattern on a metal surface

– Operational and survival temperatures

– High-temperature cycling

– 10% sulfuric acid (H2SO4)

– 10% nitric acid (HNO3)

– 20% phosphoric acid (H3PO4)

– 25% hydrogen peroxide (H2O2)

– 10% sodium hydroxide (NaOH)

– IP rating

– Compression strength

– Shocks

– Vibrations (MIL-STD-810G)

– Explosive environments (e.g. ATEX)

The results of these standard and custom tests are featured in each product’s datasheet. The Xerafy Engineering team remains available to support selecting and qualifying a tagging solution best suited to the environmental conditions in which the tags will be used.

What RFID readers work with the MICRO series?

The MICRO series tags work with standard RFID readers from Zebra, Honeywell, TSL, etc that comply with EPCglobal Gen2v2 and ISO 18000-63 standards, also referred to as RAIN RFID.

Advice is available on a selection of hands-free and handheld RFID readers with frequencies and antenna polarization matching the tags’ for optimal performance.

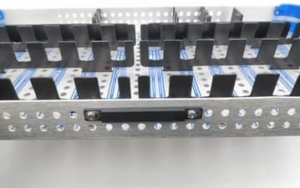

How to securely attach the MICRO series RFID tags on metal assets?

The MICRO series can be securely mounted using pop rivets, screws, cable ties, as well as industrial adhesives and glues.

The Xerafy Engineering team can advise on the mounting solutions best suited to the assets and environmental conditions in which the tags will be used.