RFID for Manufacturing And Industrial Processes

Asset availability and data collection in even the most challenging industrial processes.

RFID tracking transforms the way businesses monitor, manage, and optimize their manufacturing operations.

By employing RFID tags and readers, manufacturers gain real-time visibility into inventory, production, and logistics, contributing to overall operational efficiency and cost-effectiveness in the manufacturing sector.

While outdated production systems still rely on paperwork and spreadsheets, others have experimented with barcodes only to discover their limitations in terms of scalability and automation.

RFID offers a proven technology, that has long been used in supply chain and intralogistics inventory management to create visibility. And rugged RFID tags are available to help enhance asset availability in even the most challenging industrial processes and data collection for systems in production monitoring, quality control, traceability, and maintenance management.

RFID tags for manufacturing are designed for tracking throughout the Paint Shop, from pre-treatment, through cataphoresis, spray booth, to oven-drying and sandblasting cleaning.

The process expertise developed by Xerafy covers a large variety of industrial paint shop processes from automotive to manufacturing. We help them automate across paint types, alkaline and acidic baths, sprays and jets, temperature cycling, cleaning systems for skids, and other critical application parameters.

With a full range of RFID tags engineered for high-resistance industrial tracking systems, Xerafy’s tagging solutions reliably identify skids and other conveyors in the paint shop and go through the entire production process: Dip tanks with harsh chemicals and other pre-treatments of the surface, cataphoresis coating (KTL, E-coat), drying in high-temperature ovens, powder coating.

Our tags come with industry-grade mounting options, ensuring each tag is firmly attached to the carrier to provide reliable identification throughout the entire painting process, without identification errors or contamination risks.

Industrial RFID tags are used in the high-temp processes of Metal foundries, Composite materials, Ceramic, Concrete, Iron and Steel, Pharmaceuticals, Chemicals, among others.

Xerafy’s Industrial RFID Tags’ superior design allows them to withstand extreme temperatures, moisture, and pressure found in autoclaves, ovens, extrusion equipment, as well as the cleaning regimens they are associated with, without damage or performance degradation.

Embeddable RFID Tags for Manufacturing are designed to be injection-molded by OEMs and suppliers into their consumables, parts, and systems.

By adding RFID capabilities at point-of-manufacture, they enable the digitization of integrated supply chains with real-time information and added flexibility.

Xerafy pioneered the concept of ‘Embeddable RFID‘, be it in metal or in plastic, and offers a full range of ready-to-use and customizable products.

Dies and Molds are essential for manufacturing and RFID production tracking solutions are available in molding, casting, stamping, and cutting.

RFID tagging helps in the improvement of logistics and warehousing efficiency for all dies, plates, braille, and blades. The primary goal is to maximize availability throughout the lifecycle of the tool, from its warehouse to each manufacturing cell, by providing unique identification and enabling true traceability.

Tire production for instance involves dozens of molds for a given product, making the tracking of molds a question of operational efficiency and protection of key assets. Tracking is also involved in maintenance during the mold’s life cycle, which can reach over 30 years in some instances, with cleaning procedures scheduled to take place regularly, involving ovens, lasers, etc.

Likewise, metal foundries require to keep track of each mold to maintain availability throughout the manufacturing workflow.

RFID For Manufacturing Industry

High Temp

Survivability in extreme temperatures is critical. Rugged high-temp RFID tags surviving up to 250C are readily available. For anything above, the smart option is using tags that are easy to remove or replace.

Disposable

Find the perfect balance between durable and disposable, e.g.: High-spec reusable tags on Paint Shop skids and conveyors, or disposable labels staying with each component throughout its manufacturing workflow.

Customization

Manufacturing relies on proprietary methods and equipment, making customization capabilities a requirement: Software, readers, tags form factors, mounting options, and materials.

What are the challenges of production tracking?

Production systems require more data points, faster, and with high accuracy. Paperwork, spreadsheets, and barcodes are holding them back when it comes to automation, scalability, and durability.

High-Temp

Production environments start in the 55-110C range for cooking, pressurization, and sterilization. Temperatures up to 160C are common for industrial distillation and kilning, while chemicals are in the 90-200C range.

Complexity

Automotive paint shops, for instance, involve Temperature cycling, Water immersion, Jets, Caustic chemicals, Pressure, Shocks, Vibrations...

Data

Manufacturing systems such as Automation, Just-In-Time, and their Software depend on accurate data, which calls for industry-grade reliability and performance.

Customization

Proprietary production equipment and processes require solutions to be customizable.

Qualification

Deployment in the field involves thorough testings and qualification.

Specialized industrial RFID systems for Manufacturing

Specialized Industrial RFID systems are available to give real-time data with the accuracy and dependability required for automation, just-in-time, and custom manufacturing.

Automotive production provides a wide range of examples of RFID tracking with qualified software and hardware to capture data on the assembly line, in specialized workshops, and on the shop floor.

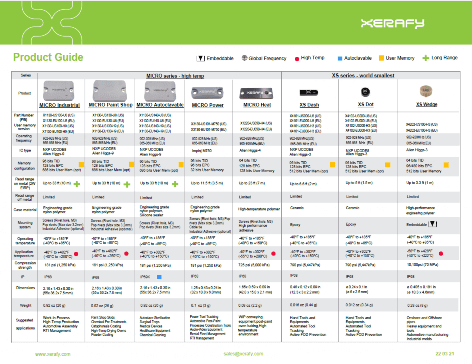

Xerafy offers a wide range of on metal RFID tags as well as embeddable versions for use in metal, with a service bureau available for printing, marking, encoding, and custom-building.