TEX TRAK series

Laundry RFID tags for textile inventory management in healthcare and hospitality

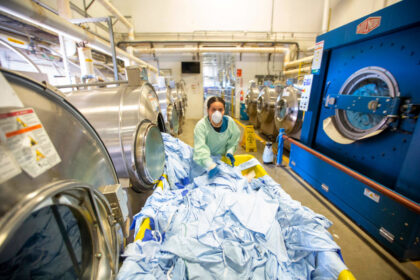

The Xerafy TEX TRAK series of washable RFID tags helps redefine how healthcare and hospitality manage textile inventory, offering unparalleled efficiency and control.

Engineered for industries where hygiene and inventory control are paramount, the RFID laundry tags cater to industrial laundries, hotels, hospitals, brands, and beyond. The high-performance RFID tags address common challenges in volume laundry tracking, ensuring a seamless process and delivering superior benefits.

Traditional laundry tracking methods often lead to errors, misplaced items, and low productivity. Say goodbye to manual tracking and hello to automated precision. With the Xerafy series of RFID laundry tags, experience streamlined processes, accurate inventory management, and enhanced security in your laundry operations.

“These innovative products help industry players reap the enormous benefits of EPC/RFID and make cost-effective tracking a reality.”

The TEX TRAK series can be combined with similar durable hard tags to cover a wider range of assets: The TRAK series of inventory tags; the OUT TRAK series of long range tags for carts and cages; the POD TRAK series for returnable laundry bins; and the XPLATE TRAK series which features a stampable design for enhanced customization. The METAL SKIN series on the other hand offers durable printable labels for on-metal tracking.

Laundry RFID Tags That Stand Out

The TEX TRAK series of washable RFID tags are engineered

to deliver the highest performance to textile inventory tracking.

Cost-Effective

Cost-effective tagging solutions for large textile inventories.

200+ Cycles

Engineered to withstand repeated commercial washing cycles.

High Temperatures

Withstand exposure to high temperatures in water, sterilizing heat, drying.

Fast and Secure

Heat-seal or sew for seamless integration into textile and optimal durability.

Unique ID

Enable item-level identification and traceability.

Customization

Tailor to specific needs to ensure a seamless integration into a laundry management system.

TEX 70x15

Medium Size Fabric

The TEX 70x15 is a UHF washable tag designed for textile inventory management.

It offers a read range of up to 13m and can withstand exposure to high temperatue in water, sterilizing heat and drying, surviving more than 200 commercial washing cycles.

TEX 50x12

Small Size Fabric

The TEX 50x12 is a UHF washable tag for small textile item management.

It's durable enough to survive over 200 commercial washing cycles. Its compact, low-profile design makes it a cost-effecive solution for large inventories.

TEX 55x12 Silicone

Small Size Silicone

The TEX 55x12 Silicone is a washable RFID tag engineered for automatic tracking and inventory in laundry applications.

Its IP68 rating and robust silicone case allows it to withstand over 200 washing cycles and sterilizing heat, drying, while the slim, flexible, soft and smooth tag case provides a comfortable fit for various textile materials.

How to Print, Mark, Encode

laundry RFID tags?

All the RFID tags in the TEX TRAK series can be fully

personalized to support the deployment of a laundry management system

Printing

Compatible with printing: Logo, brand, serial numbers

Marking

Support for permanent laser engraving: Barcode, QRcode

Encoding

Support unique IDs and EPC serialization for item-level tracking

Engineering

Support custom engineering: Size, form factor, antenna design

Case Studies

Laundry RFID tags are used for the durable identification and automated tracking of owned or rental textile inventory.

FAQs RFID Tagging with TEX TRAK series

How does RFID linen tracking work?

RFID-enabled textile tracking delivers continuous, automated visibility throughout the entire laundry cycle. Each linen, scrub, or uniform is tagged with a durable, washable RFID chip carrying a unique identifier.

As items move through the hospital laundry process, fixed or handheld RFID readers automatically capture their movements at key stages:

Collection: Soiled items are gathered and scanned, registering their return.

RFID Scan: Readers at collection points or loading bays capture bulk scans without line-of-sight requirements.

Washing/Sterilization: Items are cleaned and sterilized. RFID readers at discharge points update wash cycle counts in the inventory system.

RFID Scan: After processing, linens are scanned again to confirm readiness for delivery and update records.

Delivery/Storage: Items are tracked as they move to storage areas or are loaded for delivery back to hospital departments.

Use: Clean, compliant linens are issued to patients or staff with full traceability.

Return: Used items re-enter the cycle, scanned and logged to maintain an audit-ready record.

This closed-loop tracking system ensures every textile item has a complete, verifiable lifecycle history. Hospitals and laundries benefit from automated inventory management, reduced losses, better billing accuracy, and stronger compliance with infection control protocols.

What textile items can be tracked with laundry RFID tags?

Textile items include:

+ Hospital and hotel linens

+ Medical gowns and scrub inventory

+ Surgical supplies

+ Uniforms, costumes, and garments

How to attach laundry RFID tags?

Implementing an RFID laundry management system involves attaching RFID tags to each piece of laundry. This can be done using three standard attachment methods, with each its levels of durability and discretion:

- Heat Seal – Fastest and discreet

Heat and pressure are used to seal a plastic tag onto the textile item. - Sew On – Cost-effective

Laundry RFID tags made of fabric are placed on the textile item, with sewing lines on the tags’ extremities (Best practice: Stitch closest to a tag’s edge in order not to damage the antenna). - Sew In – Discreet

The RFID tag is inserted into a hem, in between layers, or inside a pocket of fabric (Best practices: Ensure the pocket is defined to help keep the tag in place).

Can RFID tags withstand industrial laundry processes?

Yes, laundry RFID tags like the Xerafy TEX TRAK series are engineered to ensure consistent performance through 200+ cycles of commercial standard washing:

- Water-resistance, with chemicals involving standard detergents, fabric softeners, bleach, oxygen/chlorine compounds, alkali substances, acetic and peracetic acid.

- Heat cycling through different temperatures and processes, including heat sealing, ironing, drying, steam tunnel, autoclave.

- Pressure, tunnel washer systems.

The Xerafy engineering team is available to support customers with their product qualification process.

How to integrate RFID tags into a laundry management system?

Xerafy’s laundry RFID tags are designed for easy integration into laundry management systems, by ensuring full compliance with:

- Passive RAIN RFID standard (UHF EPC Class 1 Gen 2, ISO 18000-63)

- Global RFID frequency range of 860-960 MHz

- FCC and ETSI specifications

The Xerafy engineering team is available to guide customers through a seamless implementation process.

Are there compliance requirements for laundry RFID tags?

Compliance with the following regulations and requirements are expected:

+ RoHS (Restriction of Hazardous Substances)

+ REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals)

+ OEKO-TEX® certification

+ MRI – Safe for use in Magnetic Resonance Imaging environments in medical facilities

+ RFID retail mandates

What are the benefits of RFID in laundry operations?

RFID technology enables advanced automation and traceability in laundry operations:

- Streamline sorting – RFID technology helps reduce manual labor and streamline the sorting process.

Instead of requiring individuals to read barcodes or identify linens, only 1-2 people are needed to facilitate the movement of items to the subsequent stage in the process. - Automate washing counts – Real-time accurate washing count records ensure the tracking system is updated with the latest cleaning cycle count information.

Upon discharge from the washing machine, RFID-tagged linens or clothing undergo detection by the RFID reader, which automatically identifies the RFID laundry tag sewn into the fabric. - Optimize inventory management – RFID laundry tracking supersedes manual record-keeping by introducing automated, real-time data capture.

With RFID tags integrated into textiles, inventory counts can be performed instantly, on the spot, without human errors. - Reduce loss and theft – RFID laundry tracking offers immediate insight into each inventory item, simplifying the identification and resolution of potential instances of theft or loss.

Manual inventory methods and their inherent human errors account for substantial financial challenges. - Improve customer insights – Leverage the data capture through RFID tags to provides insights into customers’ usage and preferences.

How does RFID reduce manual laundry sorting?

Traditional laundry lines often require 6–8 people stationed at sorting chutes to manually identify and direct items. RFID tags enable automatic, bulk identification of textiles as they move along the line. Readers detect each item, and software directs it to the correct chute or machine. This automation reduces staffing needs to just 1–2 people, lowering labor costs while increasing accuracy and speed.

How can RFID help track washing cycle counts?

Each high-temperature wash cycle shortens a textile’s service life. Without reliable records, predicting when items need replacement is difficult. RFID tags sewn or heat-sealed into linens are automatically read after each wash, updating software with the precise cycle count. This real-time tracking supports accurate planning, budgeting, and ensures textiles meet quality standards throughout their use.

How does an RFID tracking system improve inventory management?

Manual inventory methods are slow, error-prone, and can’t deliver real-time visibility. RFID technology automates record-keeping, capturing data as items move through key points like storage rooms and delivery docks. This provides up-to-date inventory counts, helps locate lost or misplaced items, reduces over-purchasing, and minimizes stock discrepancies—ultimately improving operational efficiency and cost control.

Can RFID reduce loss and theft?

Yes. Loss, shrinkage, and theft pose substantial costs for laundries and healthcare facilities. RFID assigns a unique electronic identifier to each item, enabling complete tracking of its movement. Staff can see where and when an item went missing, supporting loss prevention efforts and simplifying billing reconciliation with laundry service providers.

How can RFID improve customer insights?

RFID tagging not only improves tracking but also provides valuable usage data. For rental and laundry services, this includes details like renter history, rental dates, and frequency of use. Analyzing this data helps businesses forecast demand, manage stock effectively, improve service levels, and better understand customer preferences.