RFID-enabled loaner systems change this. By attaching durable, autoclavable RFID tags to surgical trays, containers, and cassettes, manufacturers can achieve real-time, field-to-facility visibility across their entire loaner fleet. RFID tracking ensures that every set is accounted for, properly sterilized, and ready for use — from the warehouse, to the trunk, to the operating room.

For manufacturers, the benefits are immediate and measurable:

Utilization – Maximize the return on investment in surgical kits by knowing where every set is, how it is used, and when it returns for reprocessing.

Compliance – Support UDI, EU MDR, and sterility validation requirements with automated traceability and quality documentation.

Integration – Connect seamlessly to existing platforms through standard APIs and data exports, while retaining full ownership of usage data.

Deployment – Scale easily, from pilot programs to fleets of hundreds of thousands of trays, with minimal infrastructure and no disruption to hospital operations.

By digitizing loaner workflows, RFID in medical industry helps manufacturers elevate service levels, strengthen partnerships with hospitals, and ensure that critical assets are available, compliant, and patient-ready.

This white paper was prepared by the Xerafy engineering team, building on years of collaboration with medical device OEMs and hospital systems worldwide to deploy RFID in healthcare. It reflects our field experience in designing, deploying, and scaling RFID solutions that meet the technical, operational, and regulatory demands of global healthcare.

The Complexity of Loaner Systems

For medical device manufacturers, the loaner system is one of the most demanding parts of their business. Orthopedic, implant, scope, and laparoscopy procedures often rely on instrument sets provided as loaners or consignment, moving constantly between warehouses, trunk stock carried by sales representatives, and hospital SPD.

Managing these assets is costly and complex. Without real-time visibility, manufacturers face:

Low utilization of high-value assets sitting idle in trunks or at hospitals.

Inefficient cycle counts and inventory reconciliation that depend on manual processes.

Compliance risks related to sterility validation, documentation, and UDI traceability.

Hospital service challenges, from late deliveries to incomplete sets that impact patient care.

Traditional tools such as barcodes, QR codes, or spreadsheets were never designed to handle the scale and regulatory requirements of modern loaner programs. Manufacturers need a system that provides end-to-end traceability and automation — from production to patient use — while minimizing disruption in hospitals.

Manufacturer Benefits: Field-to-Facility Control

Medical device manufacturers invest heavily in surgical trays, instruments, and consignment sets. With fleets that can scale to hundreds of thousands of durable assets already in circulation, the ability to track and manage them efficiently is a strategic priority. RFID-enabled loaner systems deliver measurable benefits across the lifecycle of these assets:

Utilization & ROI

Gain visibility into trunk stock and consignment inventory across the field. Knowing which sets are in a sales rep’s trunk, which are at a hospital, and which are in transit reduces idle assets and improves turnover. RFID transforms underutilized trays into productive assets, directly improving return on investment.Cycle Counts & Deployment

Manual audits of field and consignment inventory are time-consuming and error-prone. RFID automates cycle counts and reconciliation, providing accurate data in seconds. Deployment can be aligned with normal cycle counts to minimize disruption at hospitals.Compliance & Quality

RFID tags survive autoclave, EtO, and gamma sterilization cycles, ensuring sterility validation is documented for every use. Combined with UDI data capture, manufacturers can demonstrate full lifecycle traceability to regulators, auditors, and hospital partners.

Integration & Data Ownership

RFID integrates with established loaner management and ERP platforms, including SPM from Steris, LoanerLink from Censis, or SpaceTRAX from Stanley Healthcare. Through APIs and standardized data exports, manufacturers maintain ownership and control of their usage data, ensuring transparency and flexibility.

By digitizing their loaner systems with RFID, manufacturers gain field-to-facility control — improving asset utilization, meeting regulatory requirements, and elevating service levels for hospitals.

Hospital Benefits: Operational Efficiency and Patient Safety

While the primary goal of RFID loaner systems is to give manufacturers better control over their assets, hospitals also benefit directly. With RFID-enabled tracking, manufacturers can deliver instruments that are ready, compliant, and available on time, helping hospitals improve both operations and patient care:

Sterile Processing (SPD)

Loaner instrumentation introduces additional complexity into the SPD. Trays may be unfamiliar, rare, or complex, and often arrive with incomplete documentation. RFID tracking provides access to count sheets, usage history, and reprocessing records, supporting decontamination, sterilization, and regulatory compliance.Operating Room (OR)

RFID ensures the right set is delivered to the right room, at the right time, aligned with surgeon preference cards and case schedules. By integrating with OR scheduling systems such as Cerner, EPIC, and Meditech, RFID reduces case delays caused by missing or incomplete sets.Patient Safety

Automating surgical set validation and sterility checks reduces errors, improves accuracy in surgical counts, and enhances patient safety at the point of care. RFID also supports precise billing and usage documentation, improving transparency and accountability.

By partnering with manufacturers that deploy RFID, hospitals gain confidence that loaner sets are delivered, tracked, and reprocessed with the same rigor as in-house assets — ensuring both compliance and patient safety.

Technology Enablers: RFID for Loaner Systems

RFID tracking for loaner systems depends on technology that can withstand the realities of healthcare environments while delivering reliable performance at scale. Xerafy has pioneered RFID solutions specifically engineered for surgical trays, containers, and cassettes.

Tagging Technology

Xerafy’s loaner tracking solutions use passive UHF RFID tags designed for medical applications. Battery-free and field-proof, these tags provide real-time identification and tracking from the warehouse to the sales rep’s trunk, through the hospital, and back into sterile processing.

Environmental Durability

Healthcare assets are exposed to repeated sterilization and cleaning cycles. Xerafy tags are built from medical-grade 316L stainless steel and engineered plastics, ensuring resistance to:

Autoclave steam sterilization at high temperatures and pressures.

EtO and chemical sterilants used in sterile processing.

Gamma and e-beam irradiation for medical device packaging.

Shock, vibration, and handling stresses during field and hospital use.

Form Factors

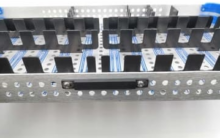

To meet the diverse needs of manufacturers and hospitals, Xerafy offers multiple RFID tag designs optimized for loaner systems:

MICRO Medical – A compact, OEM-focused tag designed for seamless integration into medical devices, providing traceability while meeting sterilization compliance standards.

ROSWELL Autoclavable – An ultra-rugged tagging solution for all types of surgical trays and containers, combining biocompatible materials with durability at the highest sterilization temperatures.

MICRO Autoclavable – Compact and robust, ideal for tracking surgical trays with an extended read range and high resistance to repeated reprocessing cycles.

Mounting and Workflow Fit

Xerafy tags are designed for straightforward integration into existing equipment. They fit standard tray holes and can be secured using rivets, screws, or inserts, ensuring a solid bond throughout the rigors of sterilization and handling. Options for removable mounting also support maintenance and replacement when required.

Why RFID Over Barcodes and Legacy Tracking

Loaner systems have traditionally relied on barcodes, QR codes, and even vision-based systems to identify and track instruments. While these tools offered incremental improvements over manual processes, they fall short of meeting today’s requirements for medical device manufacturers:

Line-of-Sight Limitation

Barcodes and QR codes require manual scanning, one item at a time, often during the busiest moments in SPD or the OR. RFID enables bulk reading of multiple trays or instruments in seconds, with no line-of-sight required.Data Accuracy and Automation

Manual barcode scans are prone to missed reads and human error. RFID automates identification and provides a complete audit trail, reducing discrepancies in cycle counts, case documentation, and billing.UDI Compliance

While barcodes can encode a Unique Device Identifier, RFID tags go further by enabling storage of UDI data directly in memory and/or the cloud, and ensuring compliance across FDA, EU MDR, and global traceability requirements.Operational Fit

RFID is fully interoperable with hospital systems already in use — including Cerner, EPIC, Meditech, SAP, WebOps, and LoanerTrak. This ensures manufacturers can upgrade from barcode-based loaner programs to RFID without disrupting hospital workflows.

The result is a step-change: RFID transforms loaner management from a manual, error-prone process into a real-time, automated system of record, giving manufacturers and hospitals the data they need to improve efficiency, compliance, and patient safety.

Elevating Service and Compliance With RFID

Loaner and consignment programs are essential for supporting surgical care, but they create significant challenges for medical device manufacturers. From underutilized trunk stock and inefficient cycle counts to the compliance risks of sterility and UDI traceability, legacy tracking systems are no longer sufficient.

RFID provides manufacturers with a field-to-facility solution that scales from pilot deployments to fleets of hundreds of thousands of trays. By automating identification and capturing data across the asset lifecycle, RFID enables manufacturers to:

Maximize the utilization of their loaner fleet.

Demonstrate compliance with global regulatory requirements.

Integrate seamlessly with hospital IT and loaner management platforms.

Deliver a higher level of service and accountability to healthcare providers.

For hospitals, the impact is immediate: loaner sets arrive complete, compliant, and on time. Sterile Processing gains traceability and confidence in reprocessing, while the Operating Room benefits from better scheduling, surgeon preference alignment, and improved patient safety.

RFID transforms the loaner system into a competitive advantage for manufacturers. It not only strengthens their ability to serve hospital customers but also protects their investments, ensures compliance, and improves outcomes for patients.

Xerafy is a pioneer in RFID for Healthcare and Medical applications, bringing to market critical technological innovations that enable advanced identification and automation capabilities.

In addition to a complete range of field-proven RFID tags available off-the-shelf, Xerafy offers Custom RFID Tags services, covering everything from a personalization service bureau to custom design engineering capabilities.