The Fessenheim nuclear power plant in the Alsace region of France has dozens of large, portable metal containers that store maintenance tools and equipment. The containers and their tool content are subject to numerous internal and regulatory controls for tool safety and security. The facility operator must know the location of all materials at all times, track and record all container movements, and provide regular audit reports.

The Centre Nucléaire de Production d’Electricité (CNPE) Fessenheim facility joined the growing number of nuclear power facilities to implement the NexCap® system from Nexess to automate its container management, tool tracking, and reporting processes. Nexess is an RFID integrator specialist for the energy and aerospace industries that is headquartered in Sophia Antipolis, France.

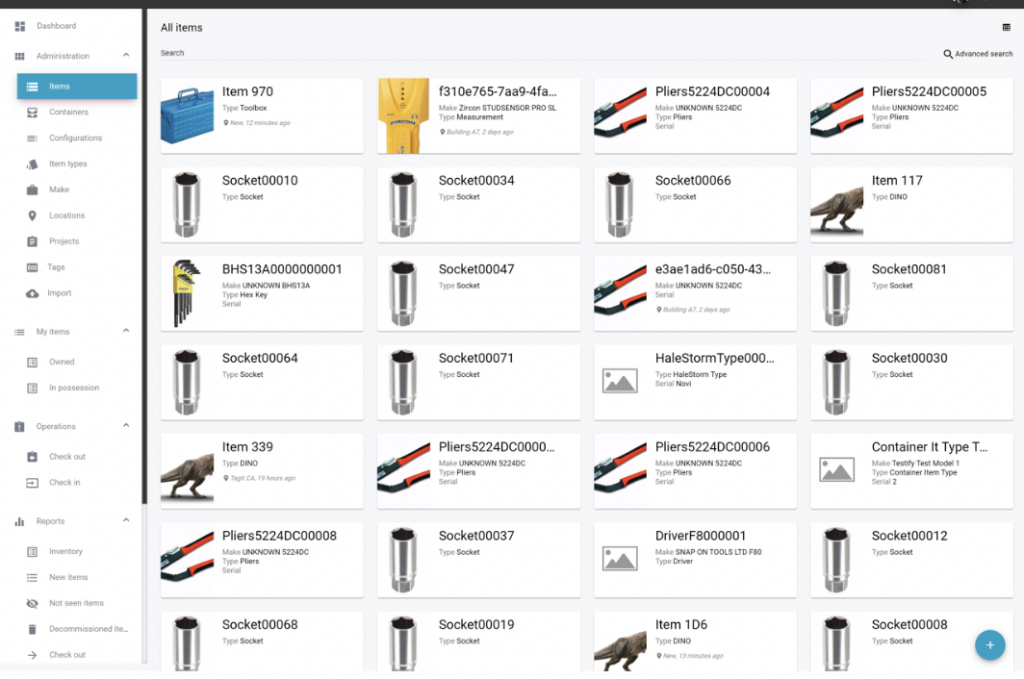

The NexCap Mobile Assets Management system at CNPE’s Fessenheim facility uses Xerafy MICRO UHF RFID tags to identify and audit storage containers, record all movements and locations, provide picking and put-away instructions to workers over a wireless LAN connection. The system also collects location and status data for reports and regulatory filings, and support materials management and maintenance operations.

CNPE estimates the container tracking system will:

Reduce the time spent looking for containers by 70%

Reduce the time needed to prepare regulatory filings by 80%

Improve forklift driver productivity 60%

Improve storage space efficiency by 50%

The MICRO tags proved a good choice for the Fessenheim facility because they are applied directly to metal containers, which are moved with forklifts and may be stored outdoors. The tags withstand the shock and vibration from rough handling plus exposure to the elements.

Xerafy is a pioneer in Industrial RFID, bringing to market several innovations that enable advanced industrial identification and automation capabilities.

In addition to a complete range of field-proven RFID tags available off-the-shelf, Xerafy offers Custom RFID Tags services, covering everything from a personalization service bureau to custom-design engineering capabilities.