Well completion marks the point where a drilled well transitions into a producing asset. In unconventional oil and gas, this phase often includes plug-and-perf hydraulic fracturing, followed by plug drill-out operations to restore full flow along the lateral. Tubing deployed during these interventions operates under high mechanical stress: joints rotate at sustained speeds, experience frequent contact with the wellbore, and are reused across multiple wells on the same pad.

The challenge for Oil & Gas operators and manufacturers alike is how to track each tubular joint throughout this lifecycle, without compromising structural integrity or disrupting rig workflows. To address this, embedded RFID was evaluated as a solution capable of withstanding extreme conditions while enabling automated identification and data capture.

A leading manufacturer of OCTG

The company is a leading manufacturer of Oil Country Tubular Goods (OCTG), supplying tubing, casing, and connectors to upstream operators across the United States. Its products are widely deployed in workover rig operations, a segment of the industry focused on mobile, high-frequency well interventions. Tubing sizes such as 2-3/8″ and 2-7/8″ are standard in these applications, supporting production, injection, and post-frac completions.

The manufacturer sought to embed durable RFID technology into its tubing to support traceability, reuse optimization, and lifecycle tracking in the field.

Operational Stress on Tubulars

During plug drill-out, the tubing string (often hundreds of joints long) is rotated at approximately 80 RPM for extended periods. These operations may span 3 to 4 days per well and involve drilling through 60 to 250 plugs, depending on the completion design.

Each time the tubing contacts the wellbore wall, wear is introduced. Over time, this abrasion accumulates, leading to wall thinning that ultimately defines the end-of-life threshold for the tubular. The embedded RFID solution had to meet several engineering constraints:

- Mechanical resilience to survive contact and rotation under load

- Consistent readability throughout the tubing’s operational life

- Preservation of pipe integrity, avoiding new points of failure in the steel body

These constraints ruled out surface-mounted tags or external markings, requiring a flush, in-metal solution designed for harsh environments.

Embedded RFID into OCTG Tubing

Xerafy’s XS Wedge passive UHF RFID tag was selected for its rugged design and proven performance in metallic environments. Specifically engineered for on-metal and in-metal applications, the tag is rated to withstand:

- Temperatures up to 438°F (225°C)

- High chemical exposure, including downhole fluids and completions chemistry

The Xerafy XS Wedge is an embedded and rugged design, with proven performance in metallic environments.

The tag was embedded into 2-3/8″ and 2-7/8″ tubing, the most commonly used sizes in workover operations. The installation process was carefully engineered:

- Three RFID tags were installed per joint (for redundancy)

- Tags were press-fit into pre-drilled chamfered holes at one end of the tube only

- The chamfer geometry enabled RF signal propagation 6–8 inches from the steel surface

- A high-strength epoxy adhesive was used to seal each tag, chosen for its compatibility with the tube’s mechanical and chemical environment

- Installation followed Xerafy engineering guidelines to ensure consistent depth, alignment, and bonding

Importantly, tags were embedded deep enough into the steel so they would only become exposed to wear once the tubing itself had reached its wear limit.

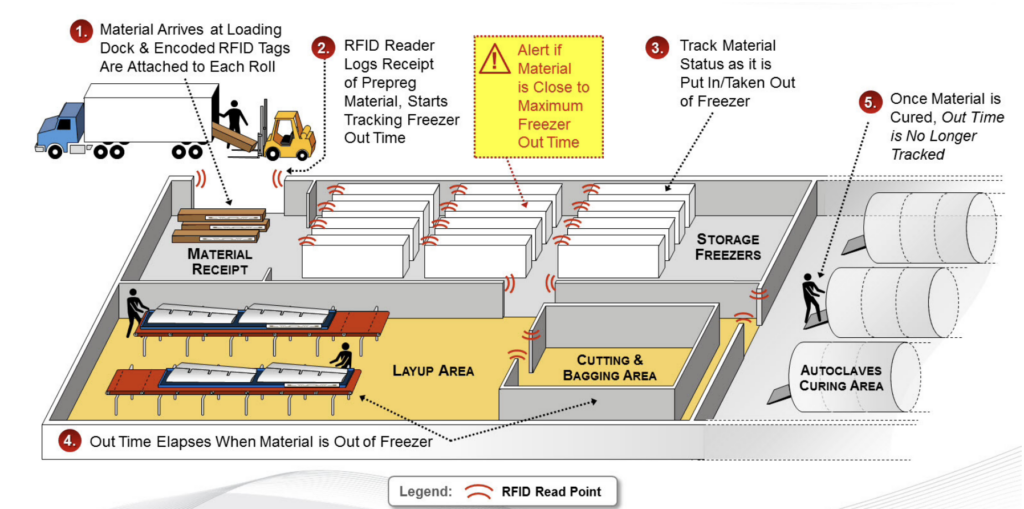

To enable scanning in the field, RFID antennas were deployed at key transition points. Tubulars were identified as they were run into the well and again as they were retrieved, ensuring full traceability without introducing new steps to the rig workflow.

Field Performance and Outcomes

This deployment demonstrated that embedded RFID tagging is viable in one of the most aggressive applications in upstream oil and gas. The benefits to both the manufacturer and operators included:

- Accurate, automated traceability of tubing across wells, pads, and service cycles

- Lifecycle tracking based on joint-level identification

- Support for reuse strategies, inventory optimization, and quality control

- No interruption to field operations, as scanning is performed without handling or manual entry

Critically, testing confirmed that RFID-equipped tubulars remained functional after 180,000 wear cycles under load. At this point, tube wall wear had already exceeded the 0.130” rejection limit, proving that the embedded tags outlasted the usable life of the pipe.

By integrating identification into the steel itself, this solution ensures that asset visibility is retained until the very last trip downhole, without compromising safety, reliability, or performance.

Xerafy is a pioneer in Oil & Gas RFID, bringing to market several innovations that enable advanced industrial identification and automation capabilities.

In addition to a complete range of field-proven RFID tags available off-the-shelf, Xerafy offers Custom RFID Tags services, covering everything from a personalization service bureau to custom-design engineering capabilities.