Tracking and Collecting Data in The Field

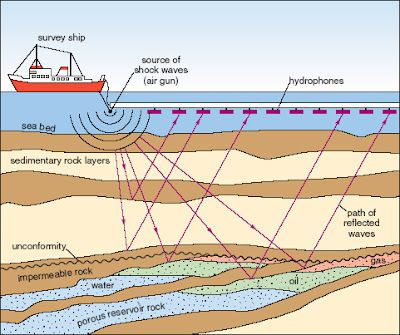

Designed to operate in extreme conditions (seabeds, marsh zones, deserts, etc.), the equipment are in operation worldwide at all the major oilfield service companies for their onshore and offshore exploration operations.

These remote locations and hard-to-reach positions add to the challenges of identifying and tracking valuable equipment in the field, compounded by a heavy reliance on manual data.

Spotting An Opportunity

The challenges became an opportunity when the oil and gas equipment vendor came up with an innovative approach: Embedding RFID features at the point-of-manufacture to identify equipment and to track them when deployed in the field anywhere in the world. The project would help redefine the company’s operations regarding manufacturing, logistics, and client services.

The project team started with a rigorous testing and selection process for the right RFID technology for the solution’s readers, antennas, tags, and software. The tags, in particular, required specific attention given the stringent operational requirements to be met. These requirements included being field-proven for demanding environments, operating on global frequencies, having the appropriate read-range, and being cost-effective for logistics applications.

“Xerafy is a highly regarded specialist in the field of RFID for mission-critical applications, and their Global Trak RFID tag came out on top of our evaluation.” – Project Team Leader

Xerafy offered its Global Trak, a Custom RFID tag design for this application, building on its popular TRAK series of cost-effective RFID tags for asset tracking, with its expertise in Embeddable RFID, and with the Oil and Gas industry.

The XPLORER Screw is an ultra-rugged embeddable tag that has been qualified for undersea operations.

Better Data, Better Service

Xerafy’s Global Track RFID tags are embedded at point-of-manufacture to enable advanced tracking and asset management applications.

The benefits of using Xerafy’s Global Trak have been most visible in the area of equipment identification, where there is increased accuracy in data collection and improved access to the relevant data. The manufacturer can now collect data in real-time, which it was unable to do in the past.

As the manufacturer places a great emphasis on data quality and excellence in its products, Xerafy’s Global Trak RFID tags have helped the company advance its product excellence by enhancing quality control procedures and reducing the risks of operating in extreme conditions.

Xerafy is a pioneer in Industrial RFID, bringing to market several innovations that enable advanced industrial identification and automation capabilities.

In addition to a complete range of field-proven RFID tags available off-the-shelf, Xerafy offers Custom RFID Tags services, covering everything from a personalization service bureau to custom-design engineering capabilities.