At the heart of tool control programs are the tool storage units – with tool cribs, chests, lockers, cabinets, and trolleys being the most popular choices. Far from being mere storage spaces, these units are central to the effective maintenance and tracking of tools and equipment. Thanks to technological advancements, these tool storage units have evolved into highly sophisticated systems, now fully automated with state-of-the-art RFID or barcode technologies.

Leading market players, such as AutoCrib, CribWise, ToolHound, CribMaster, and Hilti, showcase a wide range of innovative and capable solutions. The selection of the appropriate RFID tool tracking software is a critical decision for any organization. Key considerations include compatibility with existing systems, user-friendliness, scalability, and the capacity to integrate advanced tracking technologies like RFID and barcodes.

This guide, prepared by the Xerafy engineering team, draws upon the company’s extensive expertise in deploying RFID for tool tracking solutions across a variety of industries. Xerafy stands ready to offer further guidance and support, ensuring a smooth and successful transition to automated Tool Inventory Management.

What is a Tool Crib Software?

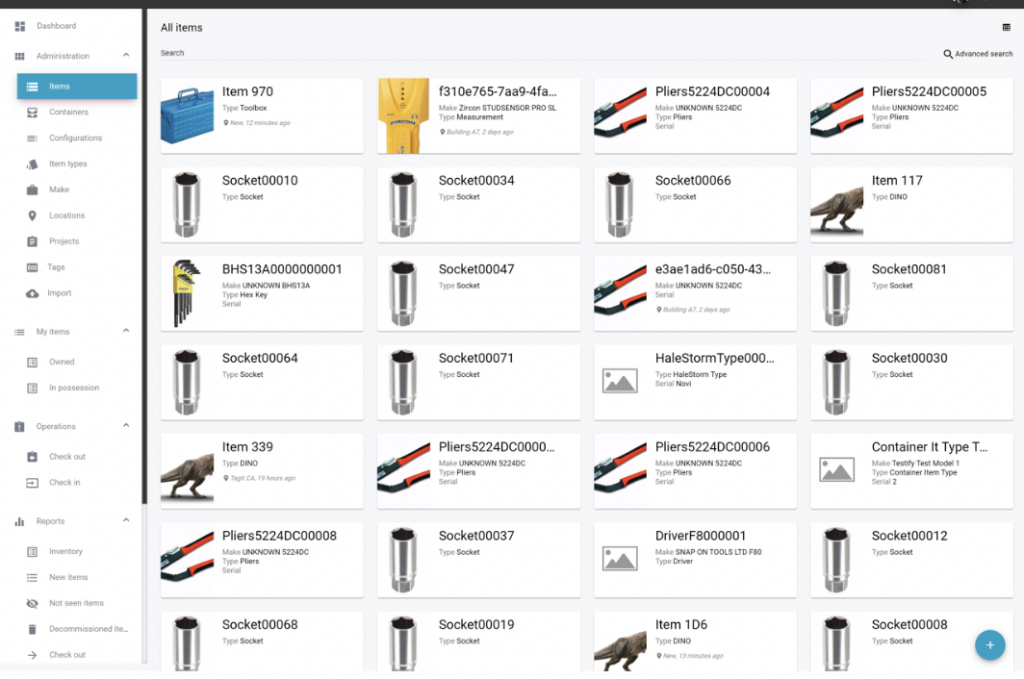

A tool crib software is a type of software specifically designed for managing the inventory of tool cribs or RFID cabinets used to store and manage the all tools and equipment.

The software comes with an automated tool crib to help keep track of tool inventory usage and levels.

The software can also generate reports to help see how the tool inventory is being used, and make informed decisions about purchasing and stocking practices.

Benefits of deploying a Tool Crib Software

There are many benefits to using tool crib software, including:

- Increased Efficiency: Quickly and easily see what tools and equipment you have on hand, saving you time and effort searching for items manually. This increased efficiency can also help you avoid delays caused by not having the right tools on hand.

- Better Inventory Control: By keeping track of your inventory levels, you can ensure that you never run out of the tools you need. This can also help you reduce waste by preventing overstocking, which can be a costly mistake.

- Improved Tool Tracking: Track which tools are being used and when, which can help you identify patterns in usage. This information can help you make informed decisions about purchasing and stocking practices, reducing waste and increasing efficiency.

- Increased Accountability: Keep track of who is using your tools and equipment. This can help you identify areas where you may need to improve training or increase oversight, ensuring that your tools are being used properly and efficiently.

Choosing the Right Tool Tracking Software: Key Features to Consider

When selecting a tool tracking software, look for the following key features to be included:

- Real-time inventory tracking: The software provides real-time updates on the availability of tools and equipment in the tool crib, allowing users to make informed decisions about which items to check out and when.

- Customizable reporting: The software allows users to generate reports on various aspects of tool crib operations, including checkouts, check-ins, and inventory levels. These reports can be customized to meet the specific needs of the user.

- Automated scanning: The software supports automated scanning, making it easier for users to quickly and accurately check out and check in tools and equipment.

- Mobile compatibility: The software can be accessed from any device with an internet connection, including smartphones and tablets. This allows users to manage the tool crib from anywhere, at any time.

- User permissions: The software allows administrators to set different levels of access for different users, ensuring that only authorized personnel can check out certain tools and equipment.

- Tool lifecycle management: The software includes features for managing the lifecycle of tools and equipment, including tracking maintenance schedules and keeping a record of repair and replacement history.

- Integration: The software can integrate with other systems, such as enterprise resource planning (ERP) and computerized maintenance management (CMMS), to provide a comprehensive view of the organization’s operations.

Barcode vs RFID in Tool Inventory Management: A Comparative Analysis

Tool identification is the first step in deploying a tool crib software, with most solutions available in the market supporting both barcode labels and RFID tags.

What to look out for when selecting barcode labels?

- Go for the extra durable, i.e. polypropylene or anodized aluminum labels, with strong adhesives.

- Prioritize customization, be it the company name and/or serial numbers.

When to use RFID tagging?

RFID tool identification uses small battery-less UHF RFID tags that can be used alongside barcodes, with the following advantages:

- Adapted to large equipment as well as very small tools, with more and more ‘RFID connected tools‘ made available by manufacturers.

- Item-level tracking with unique identifiers

- Enables active detection, i.e. at a distance, without line-of-sight.

- Automated inventory, in bulk, with limited to no human interventions.

Any other technologies to consider?

Alternative wireless technologies are available, such as BLE beacons or GPS trackers. Their price points and external power source make them best suited to niche applications.

Exploring Different Tool Inventory Software Solutions

Option 1 – Autocrib Touch ToolRoom

Best for enterprise deployments. Known for its industrial vending machines, the tool and asset control solutions specialist was acquired by Snap-on in 2020.

Option 2 – CribWise Tool Management System

Best for tooling inventory management.

Option 3 – ToolHound Tool Inventory Software

Best for specialist equipment inventories in construction, maintenance, petrochemicals.

Option 4 – CribMaster Storeroom & Tool Crib Management

Best for aerospace: The Stanley Black & Decker group’s brand enjoys high levels of recognition in the aerospace industry.

Option 4 – Option 5 – Hilti Tool Fleet Management

Best for tool fleet management.

Xerafy is a pioneer in RFID for Tool Control, bringing to market several innovations that enable advanced identification and automation capabilities.

In addition to a complete range of field-proven RFID tags available off-the-shelf, Xerafy offers Custom RFID Tags services, covering everything from a personalization service bureau to custom-design engineering capabilities.