The North American company operates the world’s largest rooftop farm. As a pioneer in urban farming, its goal is to grow food where people live. The company uses rooftop greenhouses, local farmers, and food producers to create a more sustainable food system and foster community engagement, connecting people directly with their food sources.

Their model serves as a blueprint for creating resilient, local food systems in urban environments by integrating:

Rooftop conversions: Maximizes space in dense urban areas, allowing for local food production.

Hydroponic farming: Uses significantly less water than traditional agriculture, ideal for regions with limited water supply.

Direct-to-consumer distribution: Shoppers can customize baskets of fresh food for either pickup or home delivery, minimizing waste and supporting sustainable sourcing.

The company has chosen to remain anonymous for this case study to protect proprietary information and maintain confidentiality.

Operational Challenges of Using Returnable Transport Packaging at Scale

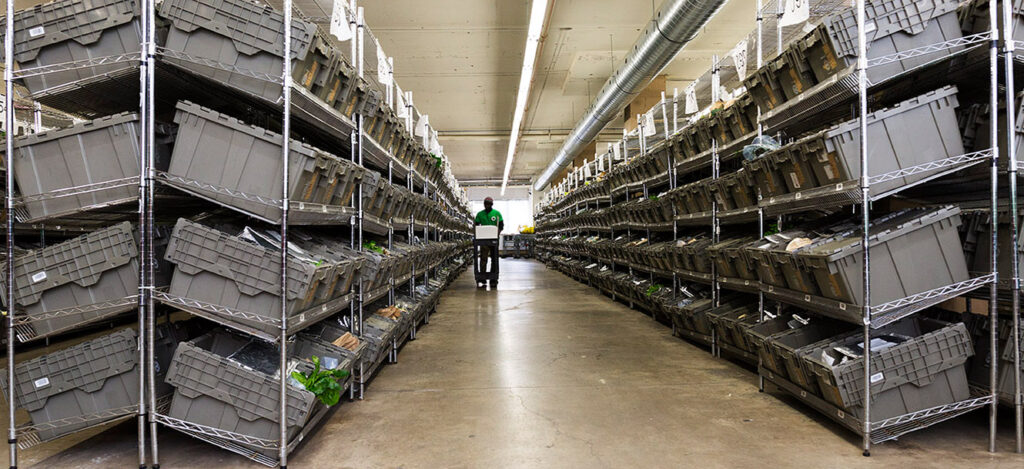

The company’s operations are complex, involving various aspects of production, logistics and supply chain. To make these complex operations more efficient and sustainable, the company relies on reusable containers throughout:

Managing the harvest of fresh vegetables across 500,000 square feet of production capacity.

Handling produce from a variety of suppliers.

Picking the appropriate produce for each made-to-order food basket.

Channeling the orders through a central distribution team.

Delivering the orders to pick-up points or homes.

Returnable transport packaging (RTP) systems are more sustainable than single-use packaging, but also more expensive when it comes to acquisition, storage, maintenance.

They require robust tracking and management solutions, including automated return verification, lifecycle monitoring, and compliance with sanitation protocols, to ensure containers are effectively returned, cleaned, and reused. Return rates can be low, particularly where suppliers and consumers are involved. Inaccurate asset tracking leads to stockouts, unplanned downtime, and resource wastage across multiple stages. Additionally, ensuring containers are cleaned and sanitized to comply with food safety standards adds further complexity.

RFID Tracking for Enhanced Efficiency and Accuracy

Asset tracking technology can help overcome these challenges by providing real-time visibility into returnable packaging inventory.

RFID stands out for its cost-effectiveness and versatility. The company was looking for a solution to standardize RTP tracking across its operations, with the following requirements:

Universal Tagging Solution: The variety of returnable containers, such as returnable plastic containers, reusable plastic crates, collapsible plastic bins, and attached lid containers, creates unique challenges for tagging to accommodate various surfaces, sizes, and uses.

Harsh Cleaning Conditions: RFID tags need to withstand high-temperature cleaning conditions while remaining readable and functional throughout the cleaning process.

Variable Storage Conditions: RTP containers are stored in a wide range of environmental conditions, from freezing temperatures (-18°C) to ambient room temperature and outdoors. The RFID tags have to handle these varying conditions without compromising accuracy.

Stray RFID Reads: In environments where returnable containers are stored closely together, RFID tags can sometimes result in stray reads, leading to inaccurate inventory data. Effective tracking solutions must address these cross-read issues to ensure precise, reliable tracking.

Xerafy offered its POD TRAK, a series of durable RFID tags designed for returnable transport packaging.

The company selected the Xerafy POD TRAK, a series of RFID tags engineered for returnable transport packaging. The key features of the POD TRAK tags include:

Durability and Heat Resistance: The tags are engineered to withstand cleaning cycles at temperatures up to 193°F, ensuring longevity and performance. They feature customizable surfaces for human and machine-readable markings.

Compact and Secure Mounting: The small form factor allows for secure attachment to tight spaces on containers using waterproof adhesives, rivets, screws, or zip ties, ensuring tags stay in place during robust handling and cleaning.

Optimized Tracking Performance: The RFID tags are designed to minimize stray reads, ensuring precise, real-time tracking of RTP throughout the supply chain.

Takeaways for RFID Tracking for RTP Tracking Projects

Companies are implementing RFID solutions for returnable transport packaging (RTP) or returnable transit items (RTI) to achieve accurate asset tracking and improve overall operational efficiency:

Enhanced Operational Efficiency: Automated tracking reduces the need for manual labor, streamlining processes and increasing productivity.

Improved Inventory Accuracy: Real-time tracking eliminates errors and provides clear visibility into the inventory of returnable plastic containers, enabling better resource management.

Cost Savings and Sustainability: The efficient reuse of returnable transport packaging lowers operational costs while supporting sustainability goals by reducing waste.

Best practices include:

Durability is Essential to ROI: RFID tagging solutions must withstand harsh cleaning and environmental conditions to maximize return on investment.

Scalable Implementation: Implement RFID solutions that can be easily scaled to accommodate future growth in container inventory and operational complexity.

Simplify Tagging and Deployment: Small, compact universal tags that are compatible with all types of reusable containers are critical for maintaining functionality and performance.

Accurate, Real-Time Tracking: Inventory management RFID solutions must minimize cross-reads and ensure precise tracking across diverse operational processes.

Xerafy is a pioneer in Industrial RFID, bringing to market several innovations that enable advanced identification and automation capabilities in manufacturing.

In addition to a complete range of field-proven RFID tags available off-the-shelf, Xerafy offers Custom RFID Tags services, covering everything from a personalization service bureau to custom-design engineering capabilities.