Comprehensive IoT Solutions are available for data center automation. They are designed to help identify, track, and secure IT Assets with very little human intervention. As such, they address the challenges of increasing inventory accuracy and decreasing time and physical labor.

Barcodes In Data Center Systems

Barcodes are a tried and tested solution in the supply chain. They provide a straightforward solution to simple issues such as reconciling incoming equipment. Compared to paper inventory, they do represent an improvement but still come with several limitations.

These are primarily due to the labor-intensive nature of reading barcodes:

- Focused line-of-sight

- Each barcode to be read individually

- One at a time

Several IT asset inventory case studies help measure the time spent to inventory 10,000 IT assets:

Paper: 50 hours

Barcode: 16 hours

RFID: 4 hours

Barcodes are unsuitable for data center automation processes such as identification and tracking. Instead, data center managers and their IT vendors look to RFID.

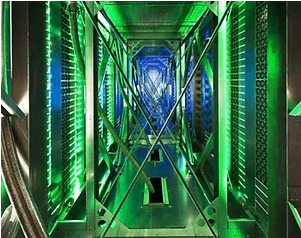

Data Center Automation With RFID

RFID allows for accurate batch reading, scanning across critical areas such as storage, inventory room, server racks. The wireless technology means identification information can be collected without having to pull servers from their racks, in bulk and at a distance, and at high speed and accuracy.

Beyond faster and more accurate data center inventories, RFID enables real-time asset visibility that translates into improved service agreement management and simplified compliance reporting. Asset utilization is improved with real-time data across locations used for effective scheduling. Security benefits from getting real-time information on equipment moving in and out of specified locations.

Regulations such as Sarbanes-Oxley and the Health Information Portability and Accountability Act (HIPAA) mandate that companies maintaining sensitive data such as financial and health records prove they own their equipment and have complete control over equipment content security. Item-level traceability, audit trails, and automated reporting, all contribute to enhancing compliance, throughout the IT asset lifecycle.

The Right RFID For Your Data Center Management Software

A typical RFID data center system will consist of tags and labels, fixed and handheld RFID readers, and then data sharing with existing processes and systems, such as an IT Asset Management (ITAM).

RFID tagging and labeling solutions are available that are engineered to fit any IT asset and device, throughout its lifecycle. One of the biggest challenges for RFID deployment in the data center is tag size and tag placement:

- Will it fit?

- Does it go on the front of the rack-mounted equipment?

- What is the read range?

- How to minimize stray reads?

- Can you attach something to the back of the chassis?

Xerafy’s extensive range of RFID tagging solutions are built on its experience with data center projects. A variety of sizes, form factors, mounting options, and tag performance levels are available:

- Metal Skin on metal RFID labels like the narrow Titanium.

- Small RFID tags like the PICO and XS series that fit on a very limited available surface, hence providing many placement options.

- RFID inventory tags like the Data TRAK and Slim SLIM offer specialized mounting options including zip tie, wire hanger, or adhesives.

- ROSWELL series of tough tags that provide a durable solution for the most demanding application environments.

Xerafy is a pioneer in Industrial RFID, bringing to market several innovations that enable advanced industrial identification and automation capabilities.

In addition to a complete range of field-proven RFID tags available off-the-shelf, Xerafy offers Custom RFID Tags services, covering everything from a personalization service bureau to custom-design engineering capabilities.