Uniform rental programs are logistics operations at scale. With garments in constant circulation (pickup, laundering, delivery, and wear) providers face pressure to reduce shrinkage, control costs, and deliver consistent service.

Traditional systems based on manual sorting, barcodes, or paper records can’t meet today’s volume and accuracy demands. Loss rates of 15% are common. Sorting is labor-intensive. Visibility is limited. Invoicing leads to disputes.

Laundry RFID tags change the equation. By assigning each uniform a unique, scannable ID that’s automatically logged throughout the laundry cycle, RFID reduces loss to under 3%, cuts sorting labor, enables per-wearer traceability, and provides audit-ready records.

This white paper, developed by Xerafy’s engineering team, outlines how industrial laundries can use RFID for item-level control, compliance, and operational efficiency.

The Operational Challenge: Where Uniforms Are Lost

Managing industrial workwear involves more than just cleaning garments. It requires precision, reliability, and accountability under operational pressure.

Breakdown of Common Pain Points:

- Shrinkage: Garments go missing in transit, get misdelivered, or are stolen. Loss rates of 10–15% inflate replacement costs and strain provider-client relationships.

- Labor Bottlenecks: Sorting garments manually by wearer or department typically requires 2–8 operators per shift. It’s error-prone and hard to scale.

- Inventory Overhead: To hedge against loss, providers overstock uniforms, tying up capital and risking obsolescence.

- Misdirected Deliveries: The wrong size or wearer leads to service disruption and frustration on the customer side.

- Inaccurate Billing: Lacking item-level proof, invoices are based on estimates. Clients complain, and providers absorb costs or enter disputes.

- Limited Lifecycle Control: Without data on usage or wash counts, providers risk non-compliant garments in critical environments.

Industry-Specific Pressures

Uniform rental providers operate across diverse industries, each with unique requirements:

- Food Processing: Must meet HACCP hygiene standards and avoid contaminant-trapping garment designs.

- Pharma & Cleanrooms: Require anti-static, lint-free suits with verified sterilization records for ISO class environments.

- Heavy Industry & Mining: Rely on flame-resistant (FR) PPE that must remain compliant after repeated industrial laundering.

- Logistics & Warehousing: Face frequent onboarding and high uniform turnover, requiring fast, accurate garment delivery by wearer.

Across these sectors, the recurring issues are the same: loss, poor accountability, compliance risk, and friction with customers.

RFID in Action: Full Visibility and Control

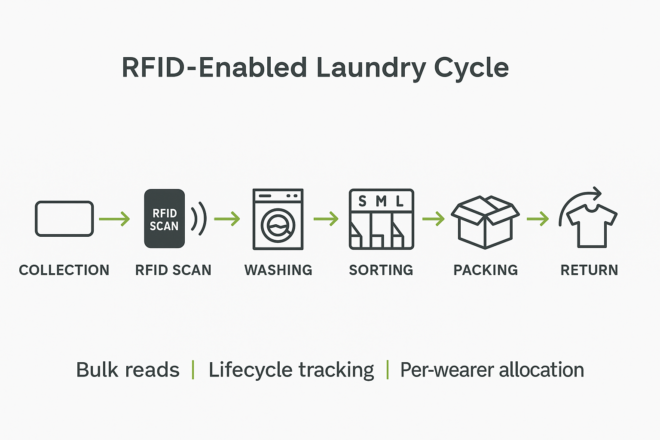

RFID tags for laundry gives every garment a digital identity tracked automatically throughout the laundry cycle:

- Each uniform is tagged with a rugged UHF RFID label, heat-sealed or sewn in to survive industrial laundering.

- Fixed readers are placed at collection, washing, sorting, packing, and loading stations to scan garments in bulk: no line-of-sight required.

- Lifecycle data, such as wash counts, is recorded automatically. End-of-life alerts enable proactive retirement and replacement.

- Customer-level visibility links each garment to a specific wearer, department, or contract, enabling precision in billing and service.

What RFID Delivers

| Before RFID | With RFID |

| 10–15% shrinkage | <3% shrinkage |

| 2–8 sorters per shift | 1–2 operators with automation |

| Manual barcode scans | Bulk RFID reads |

| Estimated billing | Itemized, defensible invoices |

| Unknown garment lifecycle | Wash counts & retirement tracking |

| Reactive customer support | Dispute resolution with data |

| Compliance exposure | Audit-ready laundering records |

From Reactive to Proactive: Operational Benefits

- Shrinkage Reduction: Real-time alerts help prevent lost or misrouted items.

- Labor Efficiency: Sorting lines are streamlined, with fewer staff needed and higher throughput.

- Customer-Level Tracking: Uniforms are tied to wearers, departments, or contracts, enabling accurate billing and service records.

- Lifecycle Management: Wash count data supports maintenance, rotation, and proactive replacement.

- Dispute Resolution: Transparent garment movement records reduce friction and restore trust.

- Regulatory Compliance: RFID logs support HACCP, GMP, ISO, and safety requirements.

Implementation Guidance: Engineering Considerations

A successful RFID deployment hinges on system-level integration and proper tag selection.

Key Elements:

- Tag Format: Choose between heat-seal and sew-in tags based on garment type and laundry conditions.

- RFID Readers: Install fixed readers at critical points (sorting lines, conveyors, loading zones). Use handheld readers for exceptions or spot checks.

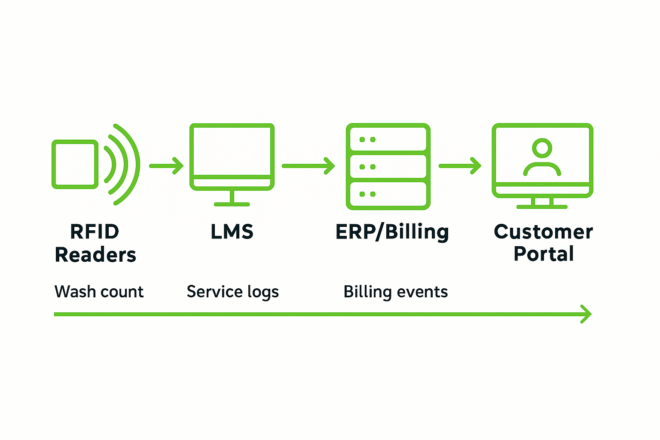

- Data Integration: Connect RFID data streams to your Laundry Management System (LMS) or ERP using APIs and middleware.

- Wash Cycle Tracking: Capture wash counts at washer exit to automate lifecycle alerts.

- Complementary Tagging: Extend traceability with RFID tags for carts, bins, and returnable containers.

Proven Applications Across Industries

- Rental Laundry Providers: Track by piece, reduce loss, automate sorting, and streamline billing.

- Food & Pharma: Support hygiene and safety compliance with verified laundering logs.

- Cleanroom & Electronics: Maintain ISO class requirements with lint-free, trackable garments.

- Mining & Heavy Industry: Replace FR PPE before failure; ensure field safety.

- In-House Laundries: Maintain internal inventory, optimize uniform availability, and reduce labor.

Why TEX TRAK washable laundry tags

The TEX TRAK series of RFID tags for laundry is purpose-built to meet the demands of industrial laundry environments:

- Rugged Construction: Withstands 200+ industrial wash cycles, high temperatures, sterilization, and chemical exposure.

- Flexible Integration: Available in heat-seal and sewn-in formats to fit diverse garment types.

- Standards-Based: Built on UHF Gen2 for global compatibility and long-range readability.

- Field-Proven: Deployed globally in high-volume commercial laundries and critical sectors.

Next Steps

Manual systems can’t deliver the control, accuracy, or visibility needed in industrial uniform programs. RFID transforms operations from reactive to proactive.

- Reduce shrinkage and disputes

- Automate sorting and tracking

- Improve billing accuracy

- Maintain compliance across sectors

- Build trust with high-value customers

Start with a TEX TRAK Test Pack and evaluate RFID traceability in your own operations.

Contact Xerafy for a technical consultation, deployment planning, or to request your evaluation kit.

Xerafy is a pioneer in Industrial RFID, bringing to market several innovations that enable advanced identification and automation capabilities in manufacturing.

In addition to a complete range of field-proven RFID tags available off-the-shelf, Xerafy offers Custom RFID Tags services, covering everything from a personalization service bureau to custom-design engineering capabilities.