Tool manufacturers and specialist solution suppliers offer a variety of off-the-shelf RFID-enabled cabinets, toolboxes, and cribs.

Xerafy shares its extensive expertise and experience with RFID technology and its applications to tool tracking, offering a comprehensive guide to understanding and implementing RFID solutions in tool management.

Examples of tool management program deployments can be found throughout industries, at businesses wanting increased visibility and accountability over high-value instruments and vital equipment:

- In airplane maintenance, tool control for aviation sockets, wrenches, spanners, and so on.

- In mining, oil and gas, and nuclear, for power tools, drilling, and lifting equipment.

- In manufacturing, it is used for CNC tools, holders, and other specialty tooling, as well as measurement instruments such as calipers and gauges and diagnostic devices.

- In logistics and warehouse management, for digital devices such as portable readers, barcode scanners, label printers, tablets, and mobile PCs.

- Armories, to store firearms and ammunition.

- For safety equipment such as harnesses and helmets, used in Oil & Gas and other sectors.

Overcoming Challenges in Industrial Tool Management

Industrial environments rely on robust tool management programs to ensure operational efficiency and compliance.

The challenges are numerous:

- Data Availability and Accuracy: Tool tracking precision is crucial, and inaccuracies in this area can result in severe operational delays and financial loss.

- Minimizing Tool Loss and Misplacement: Misplaced or misplaced tools can interrupt production schedules and increase costs, therefore prompt retrieval and management is critical.

- Tool Availability and Maintenance: Ensuring that tools are available and well-maintained is critical for avoiding downtime in production operations and extending the tool’s lifespan.

- Inventory Accuracy: Accurate inventory management is critical to avoiding overstocking or running out of necessary tools, which affects both operational flow and budget.

- Safety and Compliance: Adherence to industry-specific security and compliance requirements is critical, particularly in regulated industries, to ensure safe and legal operations.

Each of these challenges necessitates a deliberate strategy to optimize tool management while maintaining the high standards required in industrial environments.

Leveraging RFID in Tool Management Programs

RFID technology stands out for its capacity to improve tool management in industrial settings.

Unlike traditional tool management methods, RFID enables real-time tracking and automated inventory adjustments. With the help of RFID tags like Xerafy PICO series or XS series, the technology enables quick tool location, minimizing the time spent hunting for misplaced objects. Furthermore, RFID systems provide greater control over tool usage, ensuring that only authorized workers have access to specified equipment, hence improving security and lowering the danger of tool misuse.

Industrial tool management has historically relied on tried-and-true tool management methods:

- Shadow tool boards with apparent tool cuts.

- Visual tool identification, such as foam organizers in toolboxes.

- Manual check-in and check-out processes for tool rooms

- Barcodes and optical markings for identifying tools in physical cribs, chests, lockers, and trolleys

Manual tracking and documentation of tool inventories have limitations, whereas RFID tracking offers distinct advantages. Unlike barcoding, which needs line-of-sight and human scanning, RFID may be read remotely and concurrently, accelerating the tool stocking process. This capacity is especially useful in contexts where time management and accuracy are critical.

In manufacturing, RFID decreases downtime by ensuring that tools are available and operational. It is used in the energy sector to track high-value assets and ensure they are in the right location at the right time. RFID helps to make operations more efficient in various industries by optimizing inventory levels and eliminating waste.

Furthermore, RFID use in tool management is especially high in areas where regulatory compliance is critical. By providing complete usage logs and maintenance records, the system helps to ensure that safety standards and audit requirements are met. In the aerospace and defense industries, for example, a tool accountability system is crucial to prevent foreign object damage, and RFID systems provide a reliable solution to meet severe regulatory standards.

In conclusion, RFID technology offers a comprehensive solution for the challenges faced in tool management. Its ability to enhance efficiency, ensure compliance, and adapt to diverse industrial needs makes it a superior choice over traditional tracking methods.

What are RFID Cabinets for Tool Tracking?

Several industries with substantial tool inventories, such as automotive and aerospace, have successfully deployed RFID tool cabinets, significantly enhancing tool tracking and operational efficiency.

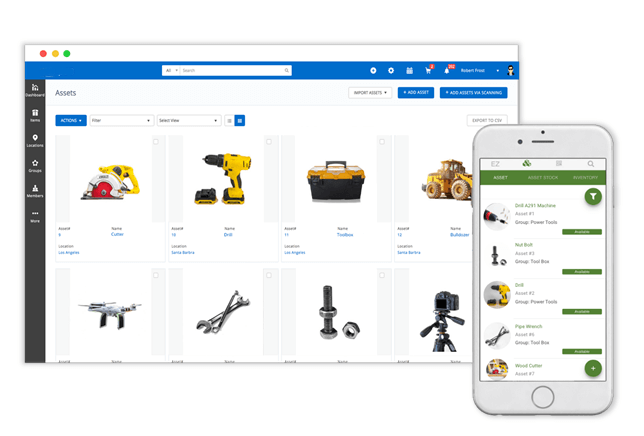

RFID tool cabinets are intended for effective tool storage and management. Their design includes RFID technology for tracking tools and equipment. Each tool is embedded with an RFID chip, and the cabinet has a reader. When a tool is removed or returned, the system instantly updates its status, enabling real-time inventory tracking.

Key features include:

- Customizable configuration: Doors, drawers, in-compartment power and charging.

- Secure enclosure and controlled access: Restrict tool access to authorized personnel only (using PIN code, access card, or biometric identification).

- Enterprise integration: Standalone or networked configuration, with real-time data made available to enterprise systems (tool usage, location, maintenance history, compliance reporting, etc).

- Automated Check In/Check Out by touchscreen with a user interface for transactions.

- Automated inventory: Provide automated updates on inventory status (capable of scanning several hundred items within a few seconds).

- Alerts and transaction audit trails are examples of advanced management capabilities.

RFID cabinets dramatically improve tool management. They shorten the time personnel spend looking for tools, automate inventory tracking, and eliminate the possibility of tool misplacement or theft. RFID lockers ensure that every tool is accounted for in high-risk areas like aviation maintenance, preventing possible hazards such as FOD.

Selecting an RFID Tool Cabinet Solution

Tool manufacturers and solution providers specializing in tool and equipment management offer RFID-enabled cabinets and lockers:

- CribMaster AccuCab

- Snap-On/AutoCrib AutoCab® FX and AutoLocker® FX

- Fastenal FAST Solutions (Industrial Vending)

- SupplyPro Inventory Management Solutions

These firms provide a range of tool management systems to meet the needs of industrial environments, including other RFID-enabled enclosures and devices such as tool cribs, carts, tables, tunnels, and gateways.

Existing tool storage could also, in theory, be retrofitted with RFID readers and antenna. However, cost-effective RFID-enabled cabinets and lockers are readily available off-the-shelf, with all the features required for tool management.

Integrating RFID Cabinets Into Your Tool Management Program

Successful deployment begins with a thorough evaluation of your present tool management program. Identify instances where RFID technology can improve efficiency and security. Analyze the types of tools used, their frequency of use, and the current issues in tool monitoring and inventory management.

Creating a comprehensive plan is critical. Choose RFID locker solutions that are compatible with your operating needs. Plan integration into existing workflows, taking into account geographical requirements and network capabilities. Prioritize seamless integration with existing operations to minimize interruption.

Implementing RFID lockers necessitates not just technological changes but also a shift in how personnel interact with equipment. Effective training programs are necessary to familiarize employees with the new system. Address any resistance to change by emphasizing the benefits and efficiencies of the RFID system. Regular follow-ups and feedback sessions can help to fine-tune the process and ensure a smooth transition.

Finally, RFID-equipped cabinets offer a transformative approach to industrial tool management.

This white paper highlights how RFID technology enhances tool tracking accuracy and inventory management through:

- Improved security and loss prevention through controlled access.

- Increased operational efficiency and time savings.

- Enhanced compliance with industry regulations and audit readiness.

- Successful implementation examples from diverse industries.

The Xerafy engineering team is available to help with further information and support regarding RFID tool management systems. Their expertise in RFID technology and tool tracking applications can guide you through the implementation and optimization of these systems in your industrial tool management program.

Xerafy is a pioneer in RFID for industrial applications, bringing to market several innovations that enable advanced identification and automation capabilities.

In addition to a complete range of field-proven RFID tags available off-the-shelf, Xerafy offers Custom RFID Tags services, covering everything from a personalization service bureau to custom-design engineering capabilities.