RFID Labeling 101

The Xerafy engineers’ guide to industry-specific applications of RFID labels to optimize asset tracking and inventory management.

Effective asset tracking and inventory management are crucial for efficient operations.

RFID labeling solutions now extend beyond traditional supply chain management, complementing hard RFID tags across various applications, from inventory and warehouse automation to asset tracking. However, with thousands of variations in face materials, adhesives, sizes, and price points, selecting the right labeling solution can be complex.

The award-winning Xerafy engineering team has created this comprehensive guide to break down how different types of RFID labels work best with various assets and inventories and offer expert advice on selecting the right labeling solution for industry-specific tracking systems.

What is an RFID label?

An RFID label is made of plastic or paper, with an embedded RFID chip and antenna and a printable face stock.

They are sometimes called Smart Labels, as opposed to disposable barcode labels, because they enable wireless tracking and additional functionalities, such as electronically storing identification information or embedding sensors (temperature, humidity, etc.). In that sense, they are fully flexible versions of hard RFID tags.

They are meant to be attached to objects or surfaces and are typically shipped in rolls, ready to be custom-printed and encoded. A wet label refers to an adhesive on the base (aka RFID stickers), while a dry label refers to no adhesive.

RFID inlays, on the other hand, consist of an RFID Chip (IC), antenna, and substrate mounted on a film face only, as they are designed to be embedded within an object or converted into another form factor. They are usually provided in zigzag or loose.

What is RFID labeling used for?

RFID labeling is the process of attaching labels on products, inventory, and company assets (such as tools, equipment, and machinery) to implement lasting identification.

RFID labels are commonly used for inventory management, supply chain, asset tracking, brand identity, traceability, and other applications that require durable marking and real-time information. They offer businesses a holistic view of their assets and operations.

How much do RFID labels cost?

RFID labels come in various sizes and formats, and the cost per label varies from a few cents to a dollar and more, depending on the label’s specialization and intended application.

The Xerafy engineering team can provide assistance in selecting the labeling solutions best suited to a project.

| Label Types | Typical Use Cases | Cost Range per Label | Examples |

|---|---|---|---|

| Durable On-Metal | Critical assets and high-value items: WIP inventory, Automotive, MRO parts, Machinery, IT Assets... | $0.50 - $1.00+ | Xeray Metal Skin® series |

| Specialty Off-Metal | Complex Supply Chains: Pharma, Medical Devices... | $0.20 - $0.70 | Xerafy XSKIN series |

| Rugged | High temperatures, waterproof, jets, solvents, acids, caustics... | $0.50 - $1.50+ | Xerafy Pod TRAK series |

| Disposable Off-Metal | High-volume labeling for retail inventory | $0.01 - $0.50 | |

| Inlays | Wet or dry inlays for Converters | $0.01 - $0.30 | |

| Sustainable | Environmentally friendly solutions | $0.15 - $0.60 | Plastic-free labels |

Are there standard RFID labels to use for specific applications?

Yes, there are RFID labeling specifications and requirements published relating to specific applications, with the Xerafy engineering team available to provide guidance and best practices on product selection:

+Automotive: Durable RFID labels with encoded identification compliant with VDA specifications, used for the supply chain management of parts and components between OEMs and their Tier 1 and Tier 2 suppliers.

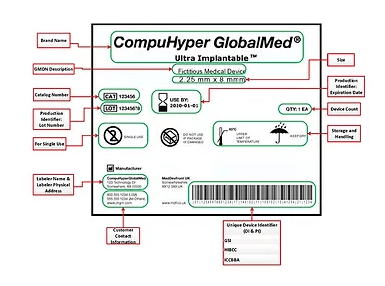

+Medical Devices: FDA UDI-compliant labeling solutions used to enforce end-to-end traceability of medical devices from manufacturers to patients.

+Military: Unique Identification (UID) requirements for Department of Defense requirements.

+Retail: RFID mandates from Walmart and other leading retailers, for suppliers to meet their labeling standards.

Which RFID labels to select for metal surfaces, plastics, glass, and liquid?

One of the determining factor in RFID performance is the surface material of the asset or packaging. Optimal performance will be achieved with RFID labels adapted to each material, which can adhere properly and maintain consistent contact with the surface. Guidance and best practices are available from the Xerafy engineering team.

Specialized labeling solutions are available that respond differently around specific materials:

1. Metal: Industrial equipment, machinery

Metal surfaces can reflect RFID signals, causing interference and reducing read range.

Specialized on-metal RFID labels are designed to overcome this issue by adding a spacer that creates a gap to shield the RF antenna from the metal.

2. Plastics: Pallets, containers, returnable packaging

Standard RFID labels perform well on most types of plastics and can be read through plastic materials, such as when embedded in a PET container.

However, specialized RFID labeling solutions are required for certain plastic materials, such as electrostatic discharge (ESD) materials used to protect electrostatic-sensitive devices.

3. Cardboard: Packaging

RFID labels perform reliably on this material as well as through it.

However, metal, liquid, and high-water contents will impact the performance. This can be mitigated by adjusting the positioning of the label or by separating items with bubble wrap or styrofoam.

4. Glass: Vials, vehicle windshield

Glass can cause signal distortion, affecting the performance of RFID labels.

Specific RFID labels are designed to adhere well and function properly on glass surfaces.

5. Liquids: Lab samples, fresh produce, bottles

Liquid and items with high water content can absorb RFID signals, reducing the label’s read range and accuracy.

Specialized on-liquid labels feature a spacer, similar to on-metal labels. Alternatively, placing the items into a container with separations is a common workaround that works particularly well for small items.

Also, most RFID labels will not work when they are wet, waterproof options are available.

6. Composite materials: Aircraft components, composite manufacturing

RFID works well on fiber glass but carbon fiber will block part or all of the RF signal (in proportion to carbon fiber content and composite material thickness).

Understanding how RFID labels interact with different materials, label placement, and orientation will help enhance reading accuracy and reliability.

It is also important to consider the impact of surface curvature on label performance: When an RFID sticker is bent, it can close its RF loop, resulting in a shortened read distance. As a guideline, a horizontally oriented label achieves 50% of its reference read-range performance with a minimum bending radius of 40mm (1.6in). For a vertically oriented label, the minimum bending radius is 25mm (1in).

How to print RFID labels?

Printable RFID labels are thicker than standard labels, making industrial RFID printers the preferred choice for custom printing:

+ Zebra ZT411R

+ SATO CL4NX Plus

+ TSC T6000e

These printers are capable of high-volume printing and simultaneous data encoding, and require compatible RFID labels.

Printing guides are available below, as well as assistance from the Xerafy engineering team.

They utilize thermal transfer printing, which ensures durability and clarity by transferring ink from a ribbon onto the label.

Software such as Bartender and NiceLabel are popular for designing and encoding RFID labels, offering user-friendly interfaces and robust functionalities.

For companies preferring not to handle in-house printing and encoding, service bureaus offer a convenient alternative, managing large volumes with high-quality results.

How to read RFID labels?

RFID labels are read using RAIN RFID readers and scanners.

Choose from handheld, fixed, or mobile readers to suit your application needs. Ensure proper antenna configuration and optimize reader settings to account for environmental factors and material considerations. Regular maintenance and the use of appropriate software further enhance performance.

Xerafy’s engineering team has put together this guide with a selection of the best RFID reader device for each application.

What is RFID serialization and how to get started?

RFID serialization is “the process of assigning a unique SGTIN (Serialised Global Trade Item Number) to a product and affixing a tag bearing that SGTIN in machine-readable form.” (source GS1)

Serialization is a key success factor in asset and inventory labeling programs. An RFID label’s EPC memory (Electronic Product Code) can be encoded with the required information. And unlike barcodes, the information can be accessed wirelessly and automatically using an RFID reader.

Proper serialization will prevent duplicate labels and interference (aka RFID clutter), with a system in place to track and manage RFID labels throughout their lifecycle, and regular audits.

The Xerafy engineering team is at hand to provide assistance on serialization and encoding.