For over a century, General Motors (GM) has been a prominent figure in the global automotive industry, producing iconic vehicles and pioneering innovations.

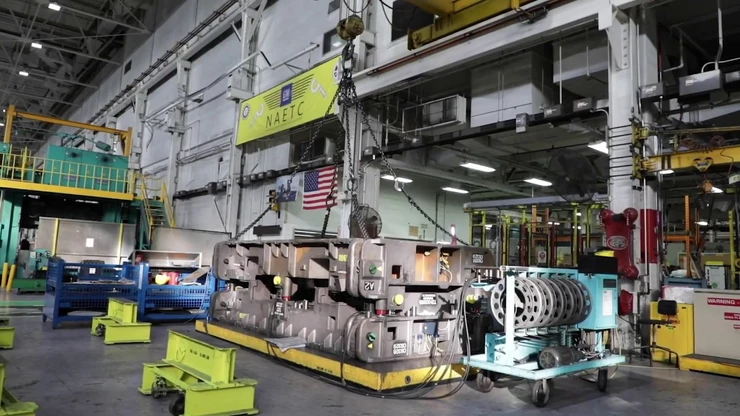

To maintain its manufacturing excellence, GM relies on a vast network of 4,000 suppliers who provide the tooling necessary for producing auto parts. These equipment have a substantial 20-year lifecycle and encompass a wide range of sizes, from small to several tons.

Tracking and managing the proprietary off-site production equipment posed a significant challenge for GM and its suppliers until they embraced RFID and Bluetooth Low Energy (BLE) technology.

Key Takeaways of RFID at GM

- General Motors (GM), an automotive industry leader, faced challenges in tracking thousands of vendor tools with lifecycles of up to 20 years.

- GM implemented RFID and Bluetooth Low Energy (BLE) technology to streamline tool tracking, reducing identification time by 85%.

- The use of RFID technology benefited both GM and its suppliers by improving efficiency and reducing manual tracking efforts.

Challenges Before RFID and BLE Implementation

Before the introduction of RFID technology, GM and its suppliers grappled with a cumbersome tool-tracking process:

- Data input requires extensive manual efforts from suppliers.

- Identification times are long, with a low first-time location rate, in need of improvement.

- Direct impact on productivity and delays.

The need for a better solution was evident, with the aim of saving manpower and labor while enhancing tracking accuracy.

Understanding Vendor Tools

Vendor tools are essential for producing auto parts in partnership with suppliers. These tools come in various sizes and frequently change location within manufacturing environments.

They endure harsh conditions, including extreme temperatures and exposure to high-temperature processes.

With a lifecycle spanning 20 years, tracking and managing these tools efficiently is paramount.

Tracking Tooling with SAP

GM had been using a module in SAP to keep track of its tools.

This system had recorded 800,000 tools to date, with 60,000-100,000 new tools added annually by suppliers. The process involved suppliers providing a list of required tools each year, after which SAP assigned ID numbers and suppliers supplied at least two pictures of each tool.

Tags were used to identify the tools, with two mandatory mentions: “Property of GM” and the ID number.

Technology Selection and Pilot Project

To address the challenges posed by the manufacturing environment, a feasibility study was conducted to evaluate RFID technology options, considering factors like vibrations, high temperatures, lubricants, dust, and long storage periods.

Various identification types were considered, taking into account read range, accuracy, and reliability. Barcodes were eliminated quickly, and active RFID was ruled out as it didn’t fit the application. Passive RFID tags, both hard and soft, and BLE tags were tested.

After a pilot project covering five sites and lasting 12 weeks with three different system integrators (SIs), BLE and RFID technology were deemed the most suitable solutions, with RadiantRFID and Xerafy selected for the deployment phase.

Results and Benefits

- BLE and RFID technology implementation reduced tool identification time by 85%.

- Achieved a 98% first-time location rate.

- Improved efficiency for suppliers, saving on manpower and labor.

- Enhanced tracking accuracy, even in challenging manufacturing environments.

- A cost-effective solution compared to alternative technologies.

- Lessons learned from pilot projects led to continuous improvement in tool tracking.

General Motors successfully transformed its tool tracking process by adopting BLE and RFID technology. This innovative approach not only streamlined operations but also strengthened the relationship between GM and its suppliers.

The case study serves as a testament to how RFID technology can revolutionize asset tracking and management in manufacturing environments, ultimately leading to increased efficiency and cost savings.

Xerafy is a pioneer in Industrial RFID, bringing to market several innovations that enable advanced industrial identification and automation capabilities.

In addition to a complete range of field-proven RFID tags available off-the-shelf, Xerafy offers Custom RFID Tags services, covering everything from a personalization service bureau to custom-design engineering capabilities.