Consider the complex journey of a beer keg – it’s not just a vessel for our favorite brews, but a key financial asset. Traditional tracking methods often led to lost, stolen, or unaccounted kegs, denting both finances and operational efficiency. Now, imagine an RFID-enabled brewery, where the flick of a scanner brings hundreds of kegs to digital life, revealing their locations and histories in an instant.

Xerafy’s RFID experts illuminate this logistical and organizational breakthrough, sharing how RFID transforms keg management for breweries of all sizes, and offering a glimpse into a future where every keg’s journey is just a scan away from clarity and control.

Navigating Complexities in the Keg Supply Chain

Managing keg inventory poses a labyrinth of challenges for beer breweries and distributors. Common issues include keg loss, misplacement, and inefficient tracking.

On average, craft brewers lose about 5% of their keg fleet each year. This loss translates to a profit reduction of $10-15 per barrel of kegged beer annually. In some cases, breweries estimate their keg loss to be as high as 20% annually (Source: The BevPros).

This represents a financial loss and disrupts inventory management and production planning. Additionally, tracking keg maintenance and ensuring quality control are crucial. Without proper tracking, kegs may not undergo necessary cleaning and maintenance, compromising the quality of the beer.

Breweries need to maintain a steady flow of kegs to meet demand, while distributors focus on efficient transportation. Pubs and restaurants rely on a consistent supply of quality beer. Each stakeholder faces unique challenges: breweries with inventory management, distributors with efficient transportation and tracking, and pubs with ensuring the beer’s quality and availability.

Traditionally, breweries have relied on manual tracking methods or simple barcoding systems. These methods, however, fall short of addressing the complexities of modern keg management. Manual tracking is labor-intensive and prone to human error. Barcodes, while a step forward, require line-of-sight scanning and struggle under the harsh conditions of transport and storage in the industry. They also fail to provide real-time tracking information and automation.

RFID vs. Traditional Keg Labels

The differences between RFID and traditional tracking methods are stark. Imagine a truck loaded with kegs passing through a gate equipped with RFID readers. Within seconds, every keg is accounted for and the inventory management system is up-to-date.

RFID allows for automated bulk scanning of kegs and provides real-time data, even from a distance. Statistically, RFID can reduce keg loss rates significantly, from an industry average of 5% to as low as 1% or less, translating into substantial cost savings.

In an industry governed by stringent quality and safety regulations, RFID offers a compliance lifeline. It ensures that each keg’s journey – from filling to delivery and return – adheres to regulatory standards. RFID tags can capture and store data like cleaning history, ensuring each keg is up to health standards. This adherence is critical, especially considering that non-compliance can lead to severe financial penalties and reputational damage.

Real-world examples highlight RFID’s efficiency but also its impact on the bottom line. A mid-sized brewery can expect to reduce its keg loss rate from 10% to just 2% within a year of implementing RFID. A distribution partner on the other hand can expect to cut down on delivery discrepancies by 90%.

The takeaway becomes clear: RFID technology is not just an upgrade but a necessity for modern beer keg management. It addresses the myriad challenges of tracking and maintenance, ensuring that breweries and their partners can focus on what they do best – brewing and distributing quality beer.

Keg Tracking Software and Solutions

The solutions ecosystem surrounding RFID technology is a critical component of its success in beer keg management. It enables breweries to extract maximum value from RFID data, providing a clear picture of their keg inventory and facilitating informed decision-making. Moreover, the solutions are designed to work in tandem with current workflows, enhancing efficiency without major disruptions.

Integration strategies may involve aligning RFID tracking with logistics, production scheduling, and even customer engagement.

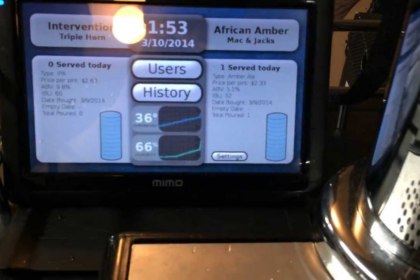

For example, a brewery will implement an RFID solution to automatically track kegs as they are filled, shipped, returned, and cleaned. It updates inventory levels in its ERP system allowing for real-time tracking of sales and inventory, and a seamless flow of information across different departments and functions. It can automatically notify logistics partners when kegs are ready for pickup, streamlining the distribution process. It provides accurate status and data to delivery personnel via mobile apps. It can analyze patterns in keg usage, helping the brewery optimize its production schedules and reduce idle inventory. It could also monitor temperature and keg integrity, ensuring the beer’s quality throughout its journey.

Several companies in the market offer outsourcing solutions where kegs are rented and managed using RFID or IOT tracking technologies and dedicated keg tracking software:

- Konvoy Kegs specializes in making keg rental simple with options for short-term rentals and long-term leasing. They offer flat rate rentals and automated location tracking on every keg.

- Microstar Logistics specializes in keg rental and management, using smart stainless steel kegs equipped with IoT-enabled tracking technology. Their system provides real-time location and detailed information about each keg, which includes data on whether the keg has been cleaned, filled, or is ready for collection.

- BevPros KegFlee offers intelligent keg leasing with built-in KegID, a barcode solution for tracking kegs

The following features collectively contribute to the effectiveness of RFID solutions in improving the efficiency, accuracy, and reliability of beer keg management processes:

- Bulk Reading Capability: RFID systems in this application can scan and record data from multiple kegs simultaneously. This feature is crucial for efficient inventory management, especially when dealing with large shipments or storage facilities.

- Real-Time Tracking: RFID technology enables real-time monitoring of keg locations. This allows breweries and distributors to have up-to-date information on their keg inventory, which is essential for efficient logistics and supply chain management.

- Unique ID: Each keg receives a unique serial number that will enable item-level data capture for vital information such as keg contents, fill dates, and maintenance history. The information can be stored in the keg RFID tag or be sent to the cloud, using the keg tracking software.

- Actionable Insights: The solution offers data analytics and reporting tools to help breweries make informed decisions based on the data captured. It can range from basic inventory management applications to sophisticated platforms offering real-time analytics, predictive maintenance alerts, and integration with broader supply chain management systems.

- Compliance and Quality Control: RFID technology aids in regulatory compliance by providing accurate data for audits and ensuring adherence to industry standards, particularly in terms of keg maintenance and product quality.

- Seamless Integration with Existing Systems: These RFID solutions can be integrated into the breweries’ existing supply chain management systems. This integration enhances the overall efficiency of operations by providing seamless data flow and analytics capabilities.

- Enhanced Security Features: RFID systems can include security features that help prevent theft and unauthorized use of kegs, ensuring that assets are protected throughout the supply chain.

Integrating RFID Systems in Keg Logistics

An RFID system for beer keg tracking is more than just tags and readers. It comprises several key components, each integral to the system’s functionality.

The RFID tag, attached to each keg, carries the keg’s unique information. The reader, equipped with antennas, sends out radio waves to activate the tags and receive data back from them. This system might also include signal repeaters to extend the reading range, particularly useful in large warehouses or distribution centers.

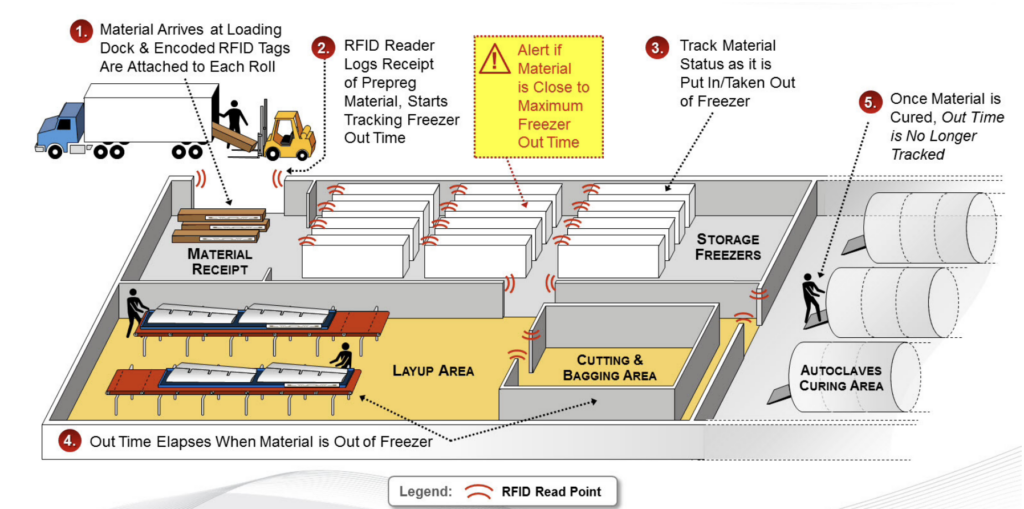

For instance, in a typical brewery setup, readers are strategically placed at key points like exit gates, cleaning stations, and loading docks. When a keg passes through these points, its tag is read, instantly updating its status in the system. This setup allows for real-time tracking of every keg throughout its lifecycle.

Integrating RFID into existing brewery operations requires careful planning. The goal is to enhance efficiency without disrupting current processes. This might involve retrofitting kegs with RFID tags, installing readers in strategic locations, and training staff on the new system. For successful integration, it’s crucial to understand the brewery’s workflow and tailor the RFID solution accordingly.

One practical example is integrating RFID data with a brewery’s inventory management software. This integration allows for automatic updates on keg status, location, and availability, streamlining the inventory process and reducing the risk of human error.

The technical aspects of RFID systems are pivotal to their effectiveness. This includes the frequency range of the tags and readers (typically UHF, or ultra-high frequency, for beer keg tracking), data storage capacity of the tags, and the durability of the components, especially important given the harsh conditions kegs often endure.

For a brewery, selecting the right RFID system means considering these technical specifications in the context of their specific needs. For instance, a brewery with a large international distribution network might require tags operating under global RFID frequencies, with a higher data storage capacity to track keg movements across different supply chain systems.

Customizing RFID Keg Tags for Enhanced Tracking

At the heart of RFID solutions for beer keg management are the tags themselves.

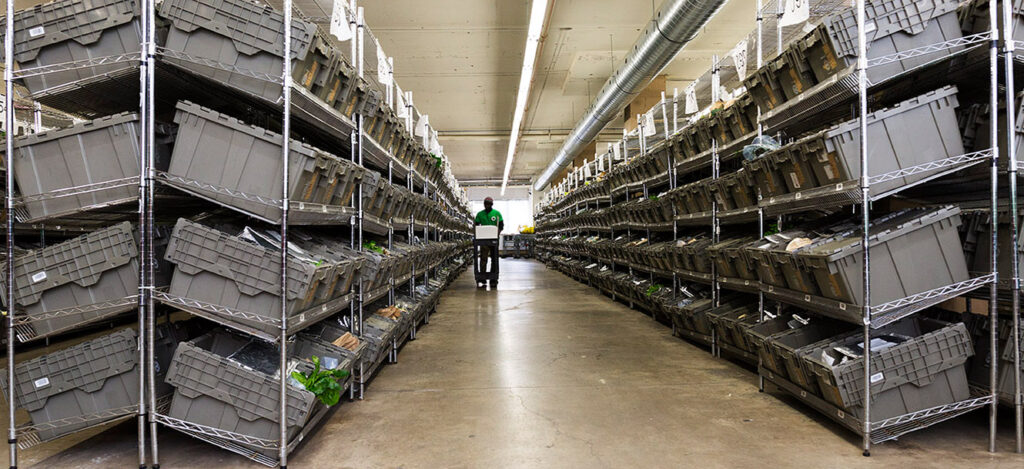

Each RFID tag contains a microchip and an antenna; when activated by a reader’s radio waves, the tag transmits data back to the reader. This technology allows for reading multiple tags simultaneously, even without direct line of sight. For example, consider a warehouse storing hundreds of kegs. With RFID, a quick scan can instantly inventory all kegs, a task that would take hours manually.

Durable UHF RFID tags like the Xylinder Outdoor are specifically designed to fit on metal kegs and cylinders for read ranges of up to 3.5 meters.

These tags are not your ordinary labels: They are hard tags specifically designed to withstand harsh environmental conditions, including exposure to high temperatures, moisture, and physical impacts common in the brewing and distribution processes. They are often encased in robust materials like ABS plastic for added protection. Durability extends to how to attach them to keg, using industrial adhesives, epoxy glue, or welding.

One size does not fit all in the world of RFID tagging, especially for beer kegs and gas cylinders that come in various shapes and sizes.

Customization is key. RFID tags can be tailored to various keg types, taking into account factors like keg material, handling conditions, and the specific data needs of the brewery. Customization options include advanced features such as battery-less sensing, as well as support for NFC and smartphones.

These cases exemplify how RFID technology can be adapted to meet specific brewery needs and keg lifecycles, transforming the traditional keg tracking process into a more efficient, data-driven operation.

Key Takeaways:

- RFID technology provides a robust solution to the challenges of beer keg tracking and management, offering real-time data, durability, and efficiency.

- Customization and integration with existing systems are key features, allowing breweries of all sizes to adapt RFID to their specific needs.

- The future of RFID in beer keg management looks promising, with continuous advancements in technology offering even more sophisticated tracking and data analytics capabilities.

The Xerafy engineering team can provide tailored, effective solutions for those seeking to implement or upgrade their keg tracking systems.

Xerafy is a pioneer in RFID for industrial applications, bringing to market several innovations that enable advanced identification and automation capabilities.

In addition to a complete range of field-proven RFID tags available off-the-shelf, Xerafy offers Custom RFID Tags services, covering everything from a personalization service bureau to custom-design engineering capabilities.