Boskalis, headquartered in the Netherlands, is a leading expert in dredging and marine engineering. Their services include land development, port construction, coastal protection, river and port maintenance, and submarine pipeline and cable installation. With a commitment to innovation and quality, Boskalis continually seeks advanced solutions to enhance their operations and maintain their global leadership.

In this case study, the Xerafy engineering team highlights how advanced RFID technology can effectively address the complex challenges associated with managing dredging pipes, particularly in demanding subsea environments.

Challenges of deploying dreding pipes

Boskalis faced significant challenges in managing the arrangement and deployment of dredging pipes.

These included:

- Technical Complexity: Dredging pipes can be very long and require specialized equipment for deployment. They must be designed to withstand the forces of dredging and harsh marine environments, and proper installation procedures are critical to ensure their integrity.

- Large Inventory: Managing a large number of pipelines, with 600 pipes deployed so far, adds to the complexity.

- Manual Management Issues: Manual management was time-consuming and costly, especially when errors occurred that required large lifting equipment to rectify.

- Subsea Application Challenges: Working in subsea environments involves additional complexities such as extreme depths, low visibility, and harsh conditions. The need for specialized diving and ROV (Remotely Operated Vehicle) support, along with the requirement to operate under high safety standards, adds to the operational challenges.

Dredging pipes come with their specific challenges:

- Wear and Tear: Dredging pipes are subjected to constant abrasion and wear from the sediments and debris they transport, requiring durable materials and regular maintenance.

- Blockages: Accumulation of materials can lead to blockages in the pipelines, necessitating effective monitoring and maintenance systems to prevent operational downtime.

- Corrosion: Exposure to saltwater and other corrosive elements can degrade the pipes over time, demanding robust anti-corrosion measures.

- Alignment and Stability: Ensuring the pipelines are properly aligned and stable during operations is critical to prevent misalignment or damage.

- Handling and Storage: The sheer size and weight of dredging pipes require specialized handling and storage solutions to prevent damage and ensure efficient deployment.

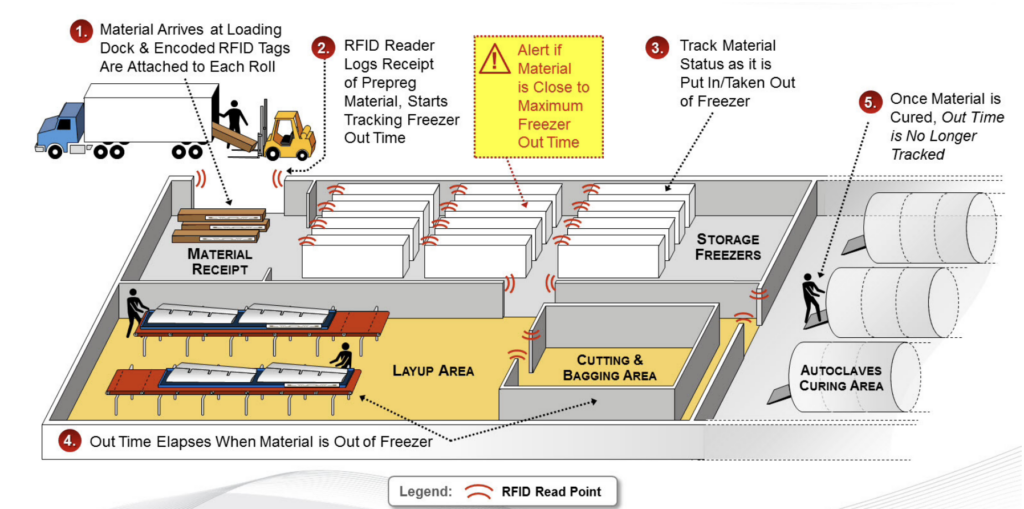

RFID Tagging Solution for Tubulars

To address these challenges, Boskalis integrated RFID technology into their pipeline management system. They collaborated with Xerafy and their pipe production supplier in China.

Xerafy offered the PICO In, a rugged embeddable tag from its PICO series of tagging solutions for pipes, tools, and equipment.

Xerafy’s PICO In RFID tags, capable of being embedded in metal, were chosen. These tags were implanted at both ends of each dredging pipe, with tags embedded in metal on each end sharing the same EPC number, ensuring readability from any angle and reducing deployment risks.

Benefits

- Enhanced Inventory Management: RFID tags accurately and in real-time track pipeline components, such as joints, bends, and connectors, reducing the risk of lost or misplaced parts and streamlining inventory processes.

- Improved Quality Control: RFID tags track the history of each component, including manufacturing date, materials, and maintenance history, ensuring each component meets required quality standards.

- Efficient Maintenance Tracking: RFID tags record maintenance activities, including inspection dates, repairs, and replacements, allowing for timely interventions and proactive management of pipeline integrity.

- Performance Monitoring: Sensor-equipped RFID tags monitor key parameters like pressure and temperature, enabling real-time health monitoring and immediate corrective actions.

Xerafy is a pioneer in Industrial RFID, bringing to market several innovations that enable advanced industrial identification and automation capabilities.

In addition to a complete range of field-proven RFID tags available off-the-shelf, Xerafy offers Custom RFID Tags services, covering everything from a personalization service bureau to custom-design engineering capabilities.