The company wishes to remain anonymous because it considers its RFID MRO tool control processes to be a strong competitive advantage. The project design and implementation were led by NG Way of Italy.

The Challenge

The company is know for innovative products and services of outstanding quality. It collaborates closely with international technology partners including Airbus, ASML, Astrium, Boeing, Bombardier, Dassault, the European Space Agency (ESA), Hilti, Krauss-Maffei Wegmann and Rheinmetall.

In particular, it operates 12 MRO, Testing and Product Development facilities in Europe and the US.

Unattended maintenance tools are a leading source of FODs which costs the aerospace industry an estimated $4 billion annually according to the FAA. Boeing has reported the cost to repair an engine that is damaged as a result of a FOD can easily exceed $1 million. FODs can also cause injuries and damage to airport facilities and support equipment.

The key to preventing FODs is controlling the environment where the damage can occur. RFID is becoming an indispensable industry tool thanks to its ability to automatically monitor environments, detect foreign objects and prevent problems.

“Our main objective is to ensure the safety during maintenance operations. The insertion of the tags on tools will allow us to eliminate any possibility of human error and will be a great help to search for any tools inside the aircraft,” said the project leader.

The Solution

The company decided to implement a project based on RFID to evaluate the possibility of creating a single software management tools.

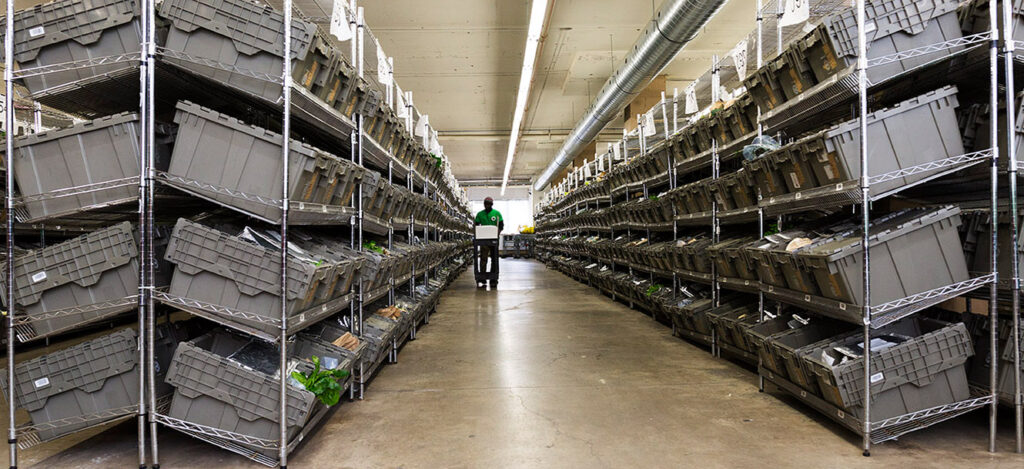

The pilot project itself began at a European facility in Switzerland and covered 276 tools such as screwdrivers, hammers, pliers and socket wrenches, of various sizes, that are stored in tool cribs.

The system relies on:

- Xerafy XS series of rugged smallest on-metal UHF RFID tags to embed into tools.

- Handheld RFID readers.

- NG Way’s ToolCheck tool crib software.

The solution is used to record which tools are assigned to technicians, track tool locations, and to verify that no tools are left behind when the maintenance activity is completed.

If a tool goes missing, supervisors can check the log to see the most recent user and location. Missing tools are quickly located using handheld RFID readers, even if the tool isn’t visible.

The system can also issue alerts when tools are not returned or when a tool calibration check is due and provides comprehensive usage data points.

“Xerafy was a natural choice,” said Moreno Poli of NG Way. “We tested many different types of tags, but Xerafy’s ability to read reliably and the minimum size of the XS series tags are unparalleled.”

Xerafy RFID tags make the system possible because they are small (as little as 2.5 mm thin for the XS Dot On) enough to be included in every tool used, and provide excellent read range (up to 2 meters / 6.6 feet for the XS Dash On) and reliability even when used on and near metal objects. The tags can be mounted directly on metal parts or embedded in the metal at the point of manufacture.

Results and Benefits

- Efficient tool inventory management

- Visibility of full maintenance history across organizations

- Improve accountability for tools management

- Loss reduction of tools

- Reduced cost of human resource

The automated tool crib software saves time compared to paper-based record keeping and manual tool searches, improves records accuracy, and makes tool status information available in real-time.

It has slashed check-in/check-out time and has significantly reduced the time spent searching for tools because it reduces the possibility of human error. Integrating the solution into the enterprise’s other asset management and resource management systems has created even greater savings, including reduced maintenance time and costs.

Xerafy is a pioneer in Industrial RFID, bringing to market several innovations that enable advanced industrial identification and automation capabilities.

In addition to a complete range of field-proven RFID tags available off-the-shelf, Xerafy offers Custom RFID Tags services, covering everything from a personalization service bureau to custom-design engineering capabilities.