Connected Assets

An RFID platform for OEMs to make smart industrial equipment

Xerafy works with OEMs to help advance the digitization of complex operations, be it in the factory, warehouse, paint shop, tool room, and other harsh environments. Its platform for Connected Assets solves the problem of repeatable and scalable RFID implementations, thus contributing to the mass adoption of RAIN RFID technology.

From Smart Products to Connected Assets

Connected Assets are best described as “smart products” designed for specific industries.

Recent examples coming to the market include items as diverse as hand and power tools, pallets, medical devices, industrial hoses, scaffolds, and power supplies. The critical equipment all come with RFID and IoT functionalities designed at the point of manufacture.

Why Make Connected Products?

Manufacturers embark on creating Connected Assets when they see the value of incorporating technology into their products. They realize how technology can help with their clients’ need to further digitize operations with built-in tracking, automating, sensing, and monitoring.

How to Develop Connected Assets?

RFID tags can be designed specifically for a tracking system’s application and deployment requirements: Read range, accuracy, user memory, fixed and/or handheld RFID readers, on-site printers and encoders, software configuration.

Making Connected Assets

With Xerafy RFID Engineering

Xerafy offers a full range of engineering services in RF technology, materials, and industrial asset tracking systems.

RFID Platforms

Extensive library of Industrial RFID platforms available

tracking technologies

Expertise in RFID and IOT technologies field-proven for industrial asset tracking

Industries & applications

Application and process expertise across industries and applications

In-House engineering

Engineering resources: RFID design, Materials, Manufacturing, Sourcing, Purchasing

Co-Development

Co-development approach supported with international project management throughout

An RFID Platform to make Connected Assets

Xerafy’s Connected Assets RFID platform provides OEMs with everything they need to transform their products into connected assets.

As an IoT technology partner to Fortune 500 companies, Xerafy benefits from a strong reputation built on innovative RFID engineering for market-leading performance and reliability in the field. The portfolio of innovations ranges from material science to using an asset’s material as substrate and designing patent-pending conformal antennas.

The company’s product co-development methodology, on the other hand, brings deep expertise in mission-critical industries such as aviation, healthcare, and oil & gas. OEMs benefit from a unique set of know-how that adds value to projects and beyond, accelerating collaborations with product designers and engineers.

What is Xerafy's Co-Development Approach?

Xerafy’s co-development approach ensures you start in no time with the support you need at every step of the process.

KEY FEATURES

Identifying the application environment and the level of performance to be achieved allows for effective validation of the custom design's MVP

FEASIBILITY

A technical and financial assessment provides the data required to finalize the business case and confirm the expected ROI

PROTOTYPING

Incremental innovation to achieve the performance required

DEPLOYMENT

Manufacturing, shipping, and full support throughout

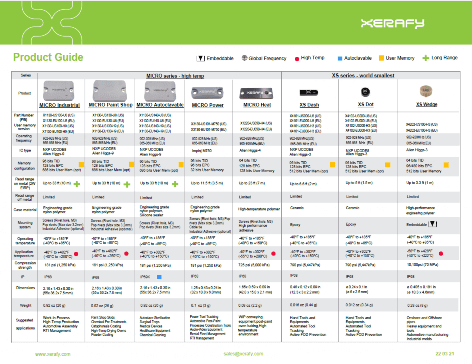

What Xerafy RFID Platform to use for Smart Products?

Explore our library of RFID platforms available in our Product Guide and Back Catalog, and speak with our engineers to design your own tagging solution.

Xerafy is the company behind some of the Industrial RFID market’s most significant breakthroughs, including the World’s smallest RFID, Most durable, High temperature, Long-range, Embeddable in metal.

Our RFID platforms offer the most advanced technologies available in the market to build tags and labels suited to your exact requirements: Form factors, sizes, materials, frequencies, memory, chips, encoding, attachment, markings, colors, branding.

Attachment, packaging, form factor: Xerafy’s own RFID tag design and manufacturing capabilities allow for unique customization capabilities, with guaranteed quality and cost advantages.